NEWS & TOPICS

Why ASTM F15 (Kovar) Seamless Tubes are the Gold Standard for Vacuum and Sealing Applications

Return to High Reliability: While resin-based packaging has become common, ASTM F15 (Kovar) remains essential for hermetic sealing in aerospace, medical, and high-vacuum sectors.

Eliminating Virtual Leaks: Kansai Pipe Industries’ seamless tubes eliminate the micro-voids (blowholes) and gaps inherent in welded tubes, ensuring superior performance in extreme environments.

Specialization in Complex Geometries: We go beyond standard round pipes, focusing on unique designs such as variable wall thickness (non-symmetrical profiles) and ultra-thin walls.

1. Market Trends: Why Choose “Kovar” Today?

With the growth of the semiconductor industry, many electronic components have moved toward plastic encapsulation or copper alloy lead frames. However, Kansai Pipe continues to receive inquiries for Kovar tubing from all over the world.

The reason is simple: there are extreme environments that resins and alternative materials cannot withstand.

- Deep-sea and Aerospace equipment requiring long-term hermeticity.

- Glass-to-Metal sealing in X-ray tubes and vacuum gauges.

- Ceramic-to-Metal sealing in high-power devices.

In these “mission-critical” areas where failure is not an option, ASTM F15 (Kovar)—which has a coefficient of thermal expansion (CTE) matching that of borosilicate glass and ceramics—remains the irreplaceable pillar of reliability.

2. Advantages of ASTM F15 (Kovar) and Our “Made in Japan” Commitment

At Kansai Pipe, our Kovar materials are primarily melted and manufactured in Japan. This ensures consistent material quality, minimizing variations in thermal expansion characteristics and supporting high-precision manufacturing.

We specialize specifically in seamless pipe manufacturing for ASTM F15 (Kovar). While it is our primary material for glass and ceramic sealing, we also support other low-expansion materials:

| Material | CTE (30∼400℃) | Our Capabilities & Characteristics |

| Kovar (ASTM F15) | 4.9–5.3 × 10⁻⁶/℃ | [Primary Focus / Standard Support] Ideal for hard glass sealing. We maintain consistent stock and production lines for this material. |

| Alloy 42 | 4.0–4.7 × 10⁻⁶/℃ | [Made-to-Order] Similar characteristics to Kovar. Production depends on raw material availability for specific projects. |

| Invar | 1.2–2.0 × 10⁻⁶/℃ | [Made-to-Order] For applications requiring minimal thermal expansion. As a difficult-to-process material, feasibility is checked per project. |

3. Preventing “Invisible Leaks”: The Seamless Advantage

In high-vacuum or high-hermeticity applications, one of the greatest concerns is the “Virtual Leak.”

Conventional welded pipes (seam tubes) may look perfect externally, but micro-voids (pockets) often remain within the weld bead. Gas trapped in these pockets is slowly released during vacuum evacuation, causing the frustrating problem where target vacuum levels are never reached.

Our Approach:

Kansai Pipe’s Kovar tubes are produced using a completely seamless process. Structurally, there is no seam, which eliminates the risk of virtual leaks caused by welding defects. We also strictly manage surface roughness to assist in the formation of the oxide layer crucial for sealing.

- Standard Specification: Ra 1.5 μm or less

- Precision Specification: Ra 0.5 μm or less

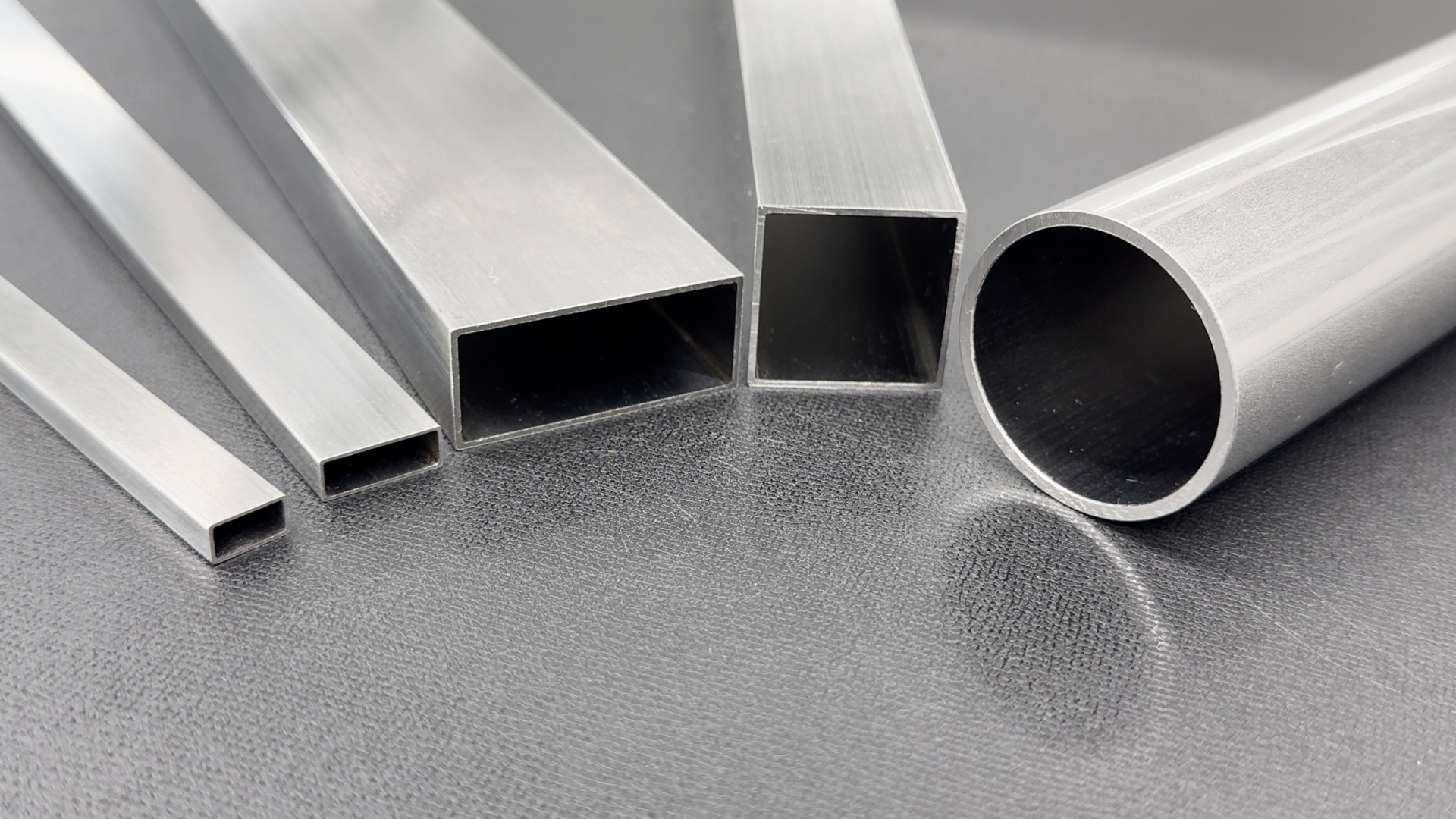

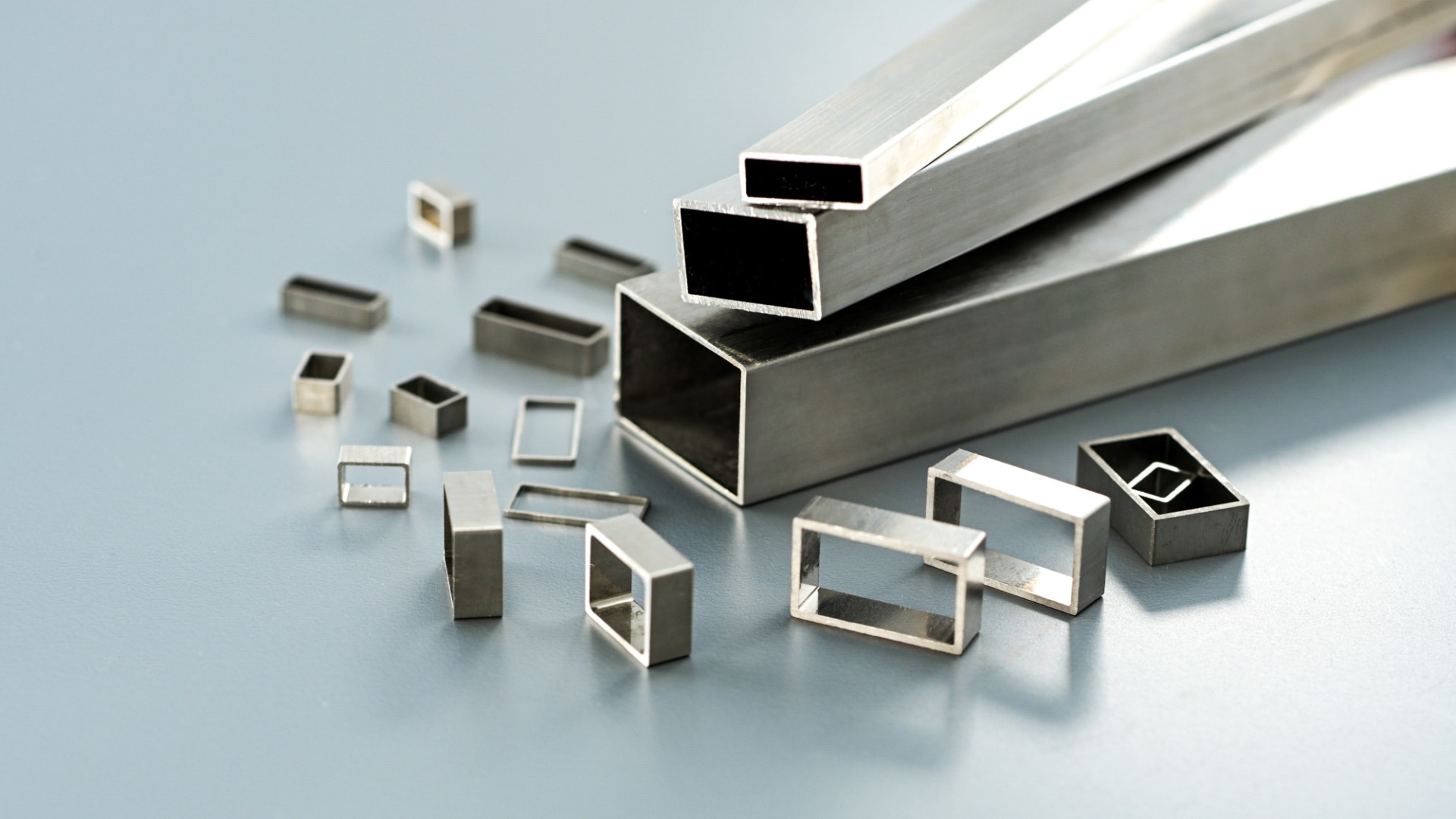

4. Advanced Applications: Complex and Challenging Shapes

Drawing difficult-to-machine materials like Kovar, which is prone to work-hardening, requires precision. We apply this technology to specialized geometries.

▼ Variable Wall Thickness & Non-Symmetrical Profiles

We respond to unique requests, such as “thickening one side for heat dissipation” or “creating special square tubes for sensor housing,” using our proprietary die designs.

▼ Manufacturing Range

- Outer Diameter (OD): Φ 5.0 mm to Φ 40.0 mm

- Wall Thickness (t): 0.5 mm to 2.0 mm

- Tolerance: From ± 0.03 mm (Consult for specifics)

- Certification: Material Test Reports (MTR) / Mill Sheets available

5. Our Commitment to R&D and Prototyping

We strive to be a “Prototyping Partner” for developers requiring high-performance materials.

- Single Piece Prototypes: We accept orders from a single unit, even when final specifications are still being determined.

- Fast Lead Times: If raw material is in stock, we aim to ship in as little as 4 weeks.

- Engineering Consultation: We focus on solving manufacturing challenges, such as feasibility of specific shapes or precision requirements.

6. FAQ

A: These are handled on a made-to-order basis. We regularly stock ASTM F15 (Kovar). Lead times for other materials depend on procurement status and order volume.

A: Yes. We can start with a hand-drawn sketch or basic dimensions (OD/ID). We provide technical consultation from the early design stages. We also accept CAD data (DXF, etc.).

A: Yes. We issue certificates proving compliance with ASTM F15 and other relevant standards.

A: Absolutely. We value “Technical Dialogue” over language fluency. Many of our international projects are completed entirely via email, without phone calls or video conferences. We utilize AI tools to ensure accurate technical interpretation. As long as you can provide drawings or data, you can consult with us from anywhere in the world with full confidence.

Editorial Note: From Our Workshop in Osaka, Japan

Kansai Pipe Industries has been dedicated to precision pipe manufacturing in Hirano, Osaka, for decades.

While Kovar was once used in mass volumes, it has now become a specialized material used where it is truly needed. Markets have changed, but our customers’ need for precision in solving difficult challenges remains constant—and has only become more critical.

We take pride in our ability to “draw hard, tough materials into precise dimensions.” Based on this core technology, we are committed to solving your “impossible” problems with sincerity and craftsmanship.

If you have been turned away by other suppliers or cannot find what you need in a catalog, please reach out to us.