Processing technology for metal materials

From material procurement of various metals to plastic forming , cutting, machining, welding and joining processes,

One-stop manufacturing from prototype development and small lot to mass production,

from design and manufacturing to secondary processing and analysis and inspection.

We can handle all kinds of pipe materials, clad pipes, irregularly shaped pipe bars, and special metal materials.

We introduce our main metal processing and manufacturing technologies.

Plasticity Processing and Material Processing

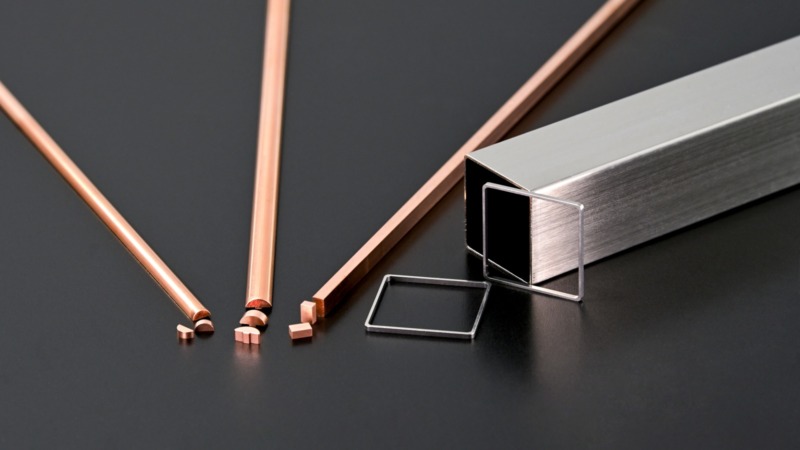

Cold Drawing

We manufacture pipes, bars, wire rods, precision materials of various metal materials with high dimensional accuracy by cold drawing. We can handle a variety of shapes including round and irregular cross sections, as well as precision pipe and bar materials such as thin-walled pipes, seamless pipes. Furthermore, we can manufacture highly functional clad materials such as clad pipes and clad rods that combine materials of different metals.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Draw bench | φ2mm - φ60mm × 6m Single type |

Various alloys, clad and deformed products | 6 |

| Draw bench (automatic) | φ1mm - φ6mm × 4m Dual type |

Mass production facilities through automation | 1 |

| wire drawing machine | φ0.1mm - 10mm × coil Single pot type |

Various alloys, clad and deformed products | 6 |

| Continuous Drawing Machine | φ0.05mm - 1.0mm 1 bobbin max 10kg |

Fine wire drawing | 1 |

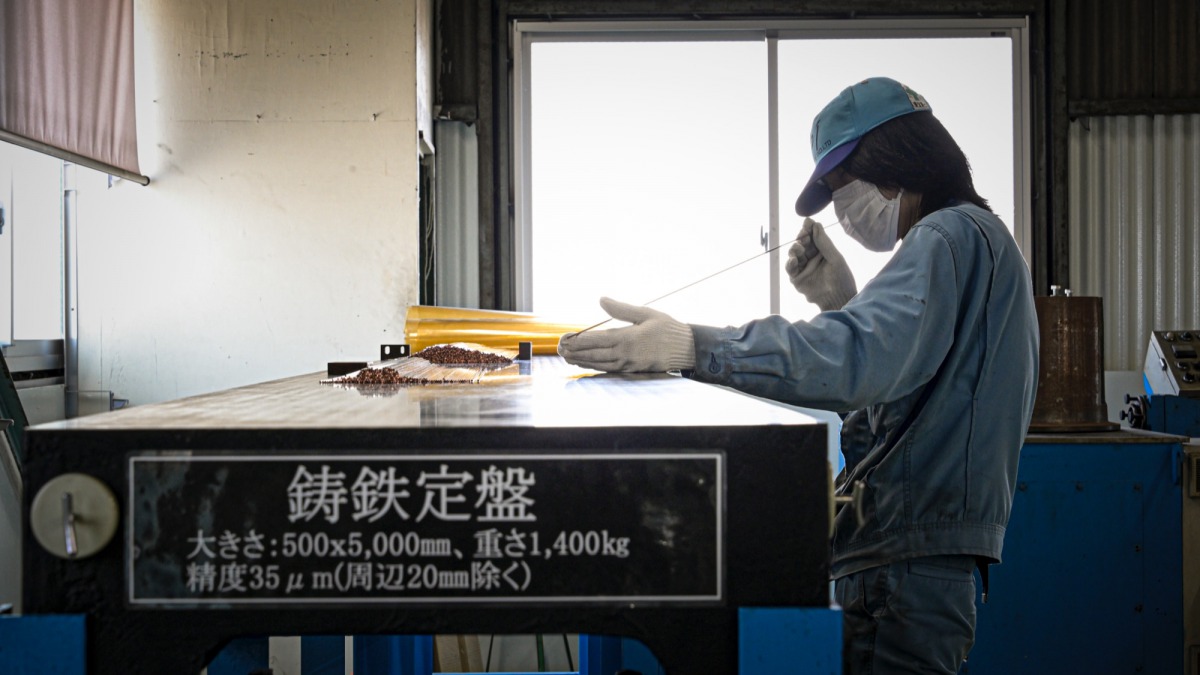

Straightening

Straightening and finishing of coil material and tube bar material. Straightening of precision parts and ultra-fine wire materials, for which flatness, warping, bending, and other qualities are strictly required, is handled for finishing.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Multi-Roll Straightening Machine | φ2mm - φ40mm Rigidity 0.3/300 or less |

Precision Straightening | 4 |

| Leveler Straightening Machine | t0.3 - t5.0 × W600mm | Stretching and straightening of short plates and FBs | 1 |

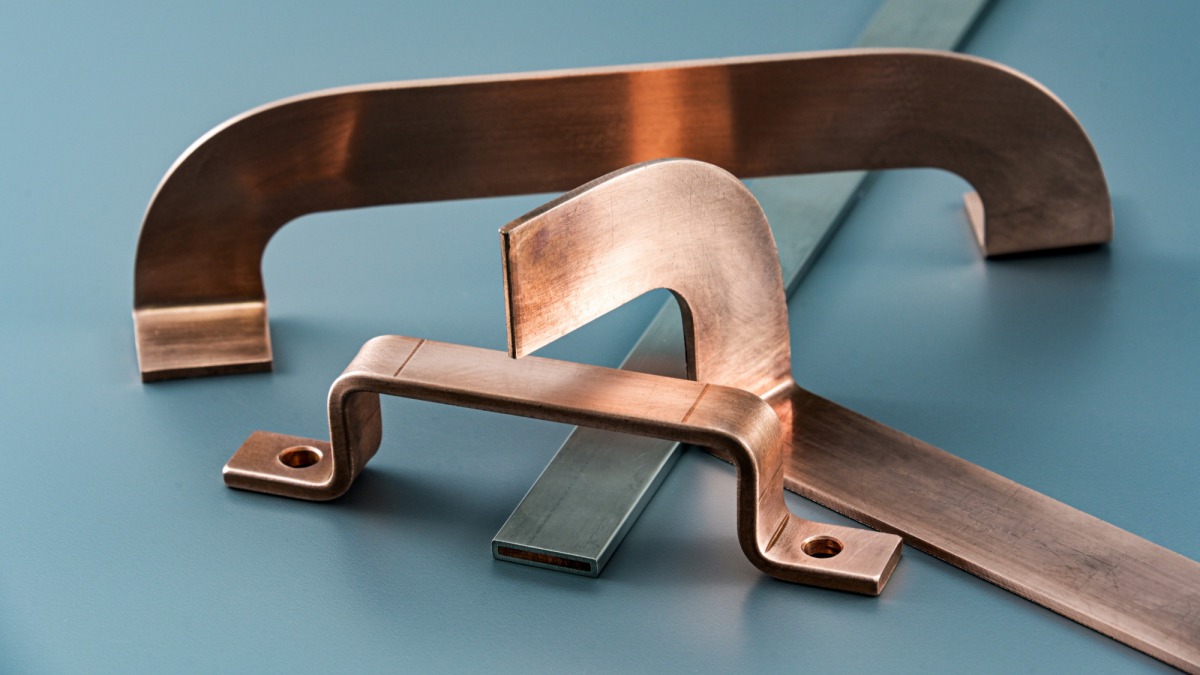

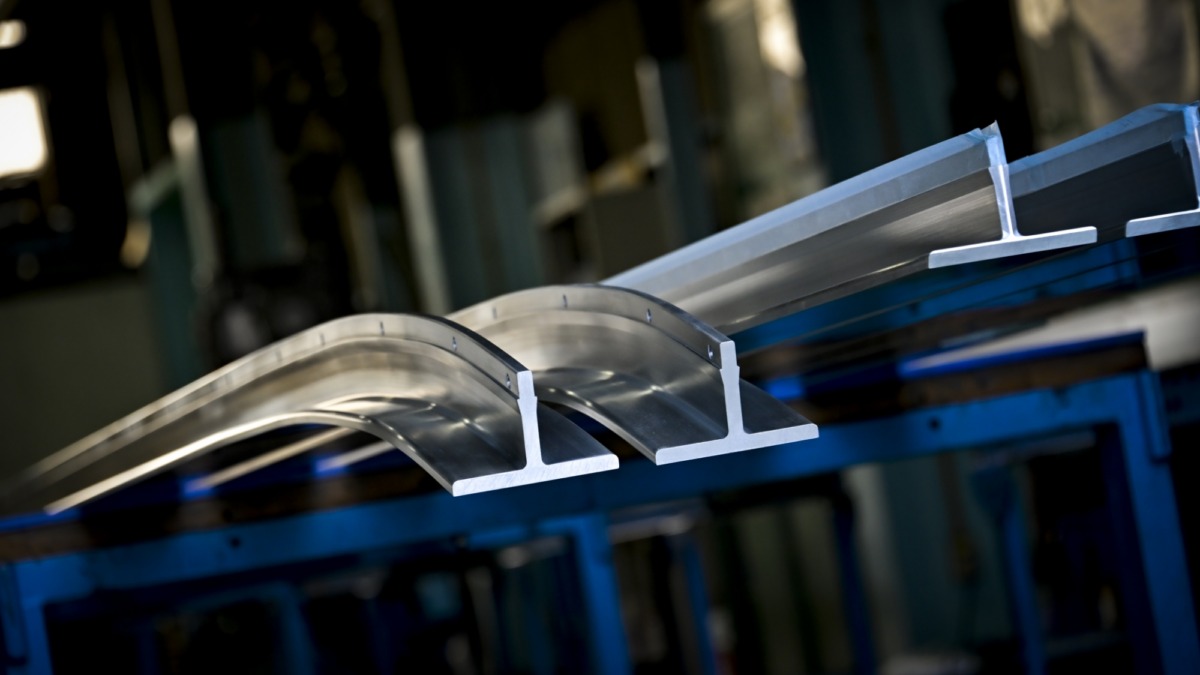

Bending

We can handle bending to any shape. We manufacture many products such as pipes, bars, plates, and bus bars. Please consult with us about difficult-to-process metals, small and large diameters, and any other sizes, including secondary processing.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Pipe bender | Max φ19mm | Deformed, bus bar processing possible | 1 |

Heat treatment (annealing, solution treatment, stabilization treatment)

Metal heat treatment processing with high dimensional accuracy is possible in atmospheric, CO, vacuum, and hydrogen atmospheres.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Bright annealing furnace | W1000mm × H100mm Max 850°C |

Reducing gas, continuous | 1 |

| Annealing furnace | 1m × 6m Max 500°C |

Atmospheric, batch | 1 |

| Quenching furnace | φ800mm × 4m Max 600°C |

Atmospheric, batch | 2 |

| Vacuum furnace | φ150mm × L150mm Max 1000°C |

Atmospheric, batch | 1 |

| Rotary kiln | φ45mm or less, length 2000mm or less Max 600°C |

Heat treatment in atmospheric atmosphere | 1 |

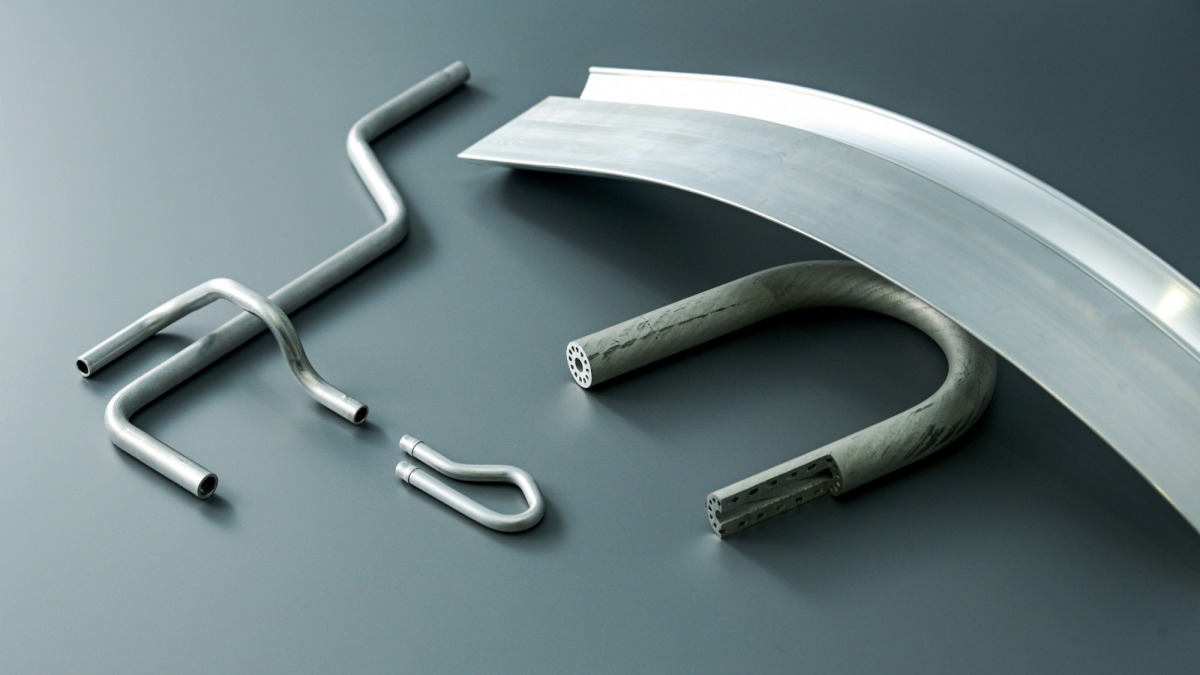

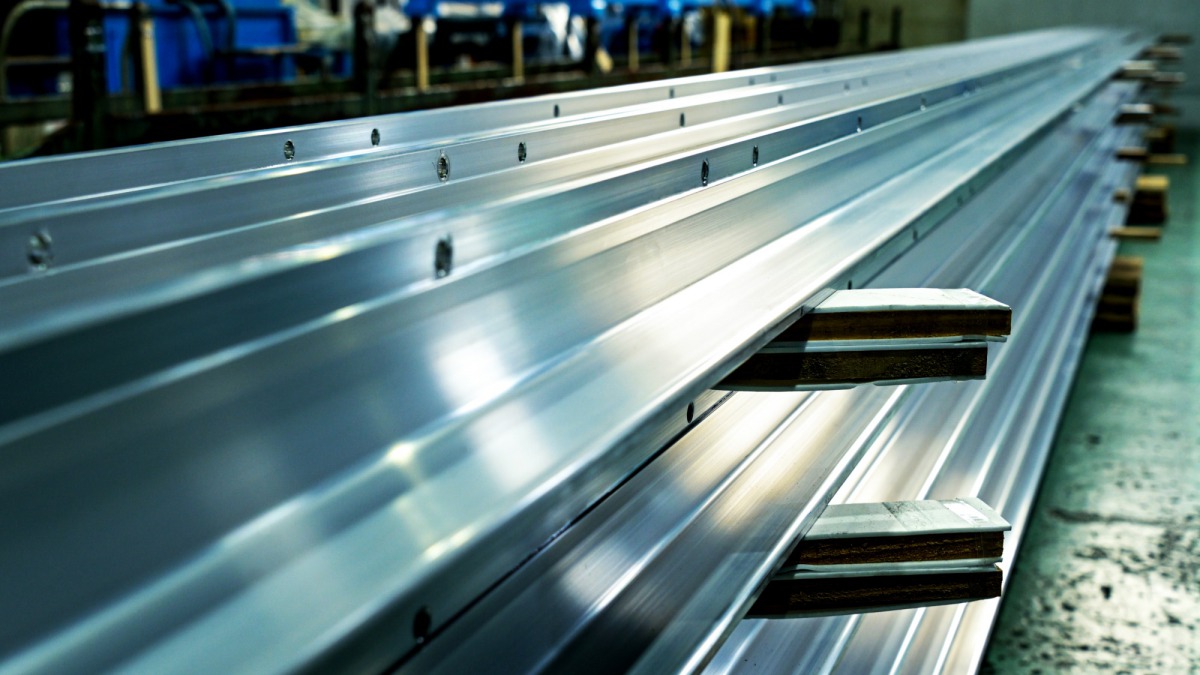

Twist processing of long materials, Finning

We can manufacture long twist processed pipes and fins up to 10m in length. We manufacture various heat exchanger components with excellent corrosion resistance and light weight, such as aluminum alloy fin tubes (inner grooved tubes).

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Twisting | Max length 10m | Twist processing mass production machine Equal pitch and equal interval twisting is possible |

1 |

Swaging fabrication process

Swaging processing of pipes, bars, and wires with round cross sections is available. From swaging processing as a material to precision processing for medical parts, etc.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Swaging machine | φ0.3mm - φ60mm Rated length material, Coil |

Proposal of processing that takes advantage of the characteristics of metals | 6 |

Flare finish

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Pipe end processing machine | φ4mm - 19mm | Flare, aperture, beading | 1 |

Machining

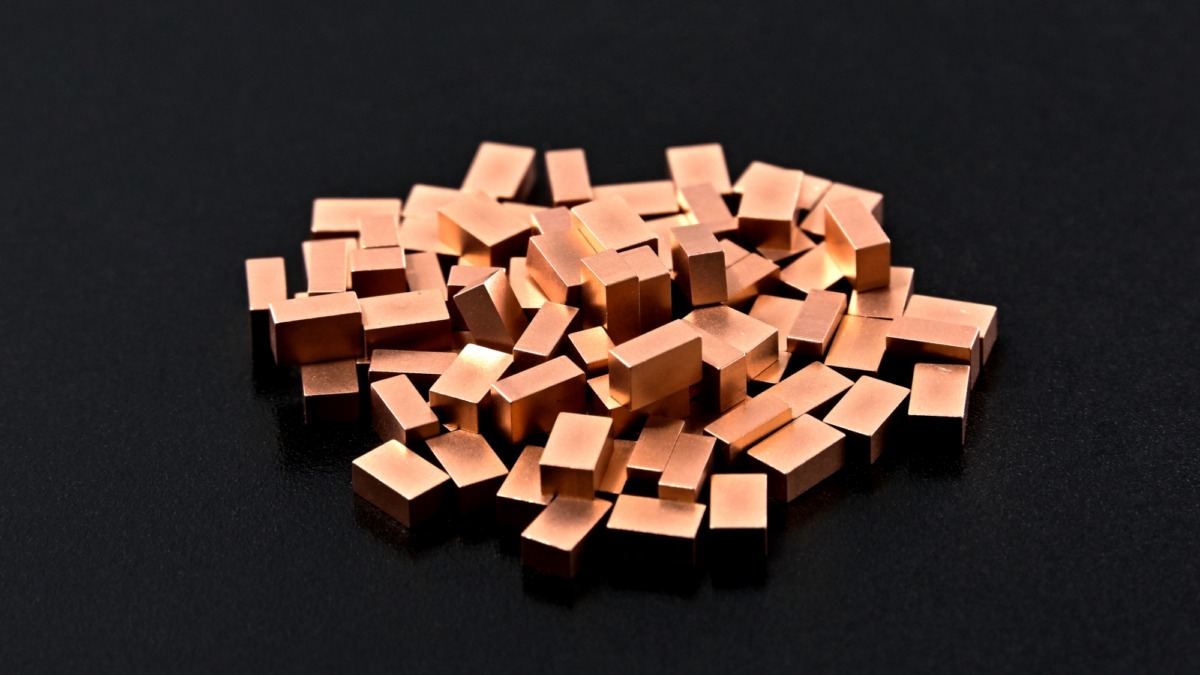

Cutting, Turning, Drilling

We can cut and drill pipes, bars, wires, plates, and other materials of any dimensions.

With machining centers, NC drilling machines, and semi-automatic lathes, we are a one-stop shop for machining parts that require complex technology, such as difficult-to-machine materials and clad pipes.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| High-speed circular sawing machine | 240mm × 150mm ×1000mm | Precision cutting of copper and aluminum | 7 |

| 3D Circular Sawing Machine | 400mm × 200mm × 4000mm | Cutting of large aluminum extrusion molds, etc. | 1 |

| Circular sawing machine | 280mm × 100mm × 3000mm | Precision cutting of copper and aluminum | 1 |

| Precision Grinding Wheel Cutting Machine | φ20mm or less Cutting tolerance ±0.1 or less |

Precision cutting of iron, stainless steel, etc. | 2 |

| Multiwire saw | 150mm ×150mm × 300mm Cutting pitch 0.5mm to 5mm |

Mass production facilities for short products and ultra-precision cutting | 2 |

| Chip Saw Cutting Machine | Max φ100mm | Cutting of various metals | 5 |

| Contour machine | t250 × W600mm | Steel plate cutting | 2 |

| Bandsaw | φ120mm | Steel cutting process | 1 |

| Machining center | 1050mm × 560mm × 520mm #40, 12,000rpm |

Precision Cutting | 1 |

| Machining center | 2000mm × 350mm × 400mm #40, 8,000rpm |

Precision cutting of long products | 1 |

| Machining center | 500mm × 400mm × 300mm #30, 2,400rpm |

Precision cutting, mass production, prototype machines | 1 |

| NC Drilling Machine | 5,000mm × 350mm × 300mm #30, 8,000rpm |

Drilling and cutting of long products | 1 |

| Reuter | 200mm × 100mm | Milling of resin, etc. | 2 |

| General-purpose milling cutter | 900mm × 200mm × 200mm #400, 1,400 rpm |

Cutting of various metals | 1 |

| Simple NC Lathe | 1000mm between centers | Semi-automatic precision turning | 1 |

| NC Cutting Machines | Max φ70mm | Mass production by dedicated machine (aluminum round bar) | 2 |

| Drilling machine | ― | ― | 5 |

Press

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Hydraulic press | 30t | Mass production facilities for architectural hardware, cable racks, etc. | 1 |

| Vendor press | L=1000mm 60t |

Mass production facilities for architectural hardware, cable racks, etc. | 1 |

| Servo press | 60t | Precision Pressed Parts | 1 |

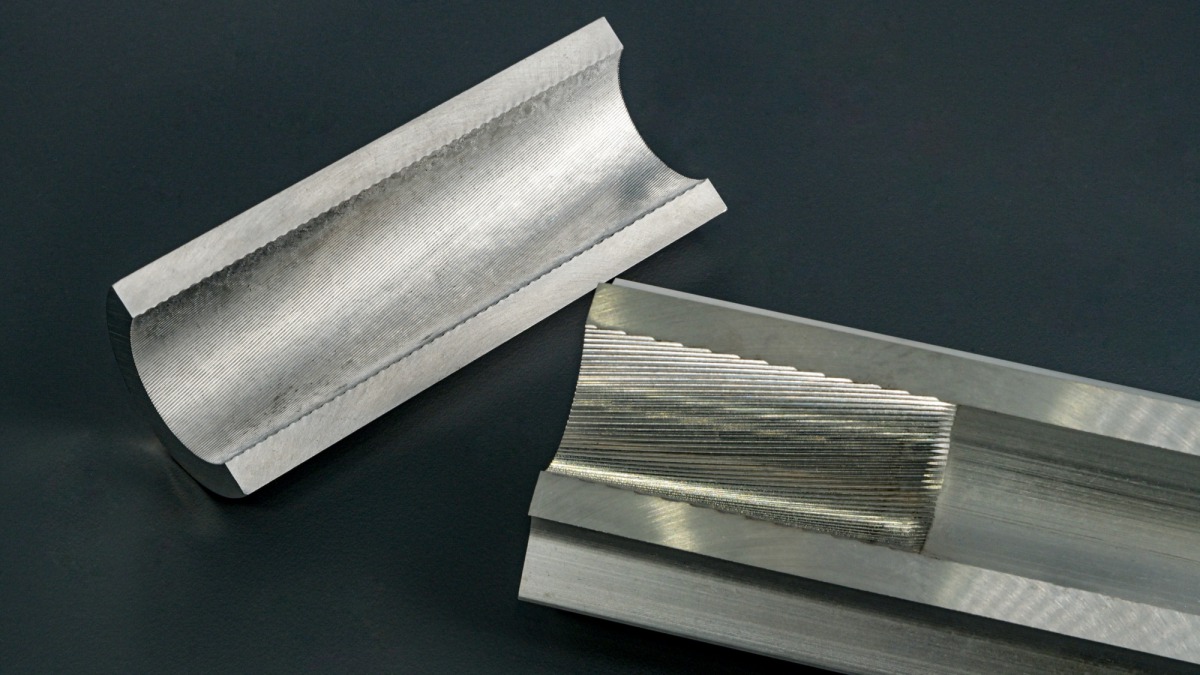

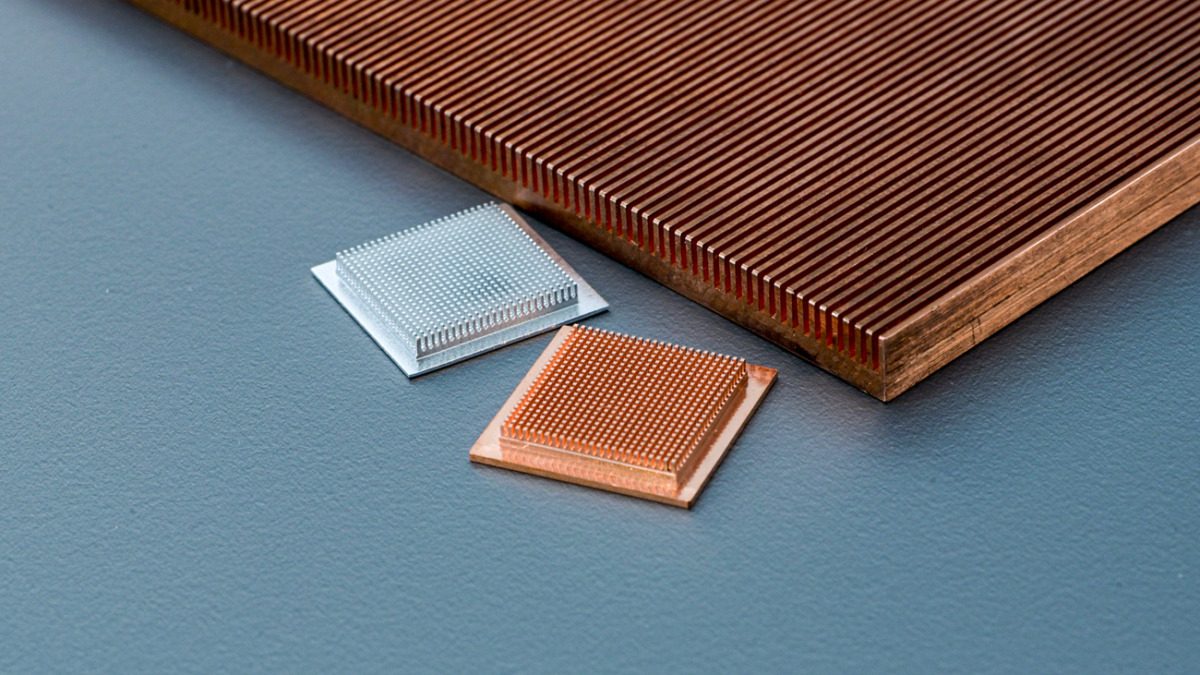

Precision slitting and Precision cutting

We can handle mass production of precision metal parts using ultra-precision cutting machines. We are capable of slitting fine slits with widths of 0.1 mm to 0.5 mm, etc. and producing surface fins to manufacture semiconductor-related materials such as heat sinks and precision electronic parts.

Surface Preparation and Polishing

We can handle external polishing, internal polishing, and barrel polishing for various metal materials as internal, external, and various finishing processes.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Sandblast | 500mm × 600mm × 500mm Abrasive circulating type |

Prototype | 2 |

| Barrel Finishing Machine | Barrel capacity 65l Filling volume 65% |

Chamfering, deburring | 1 |

| Vibratory Barrel Finishing Machines | Barrel capacity 28l Filling volume 68% |

Chamfering and deburring with minimal dents and abrasions | 1 |

| Washing tank | 1.4m × H2m tank Nitric acid, caustic |

Coils, molds, rods | 2 |

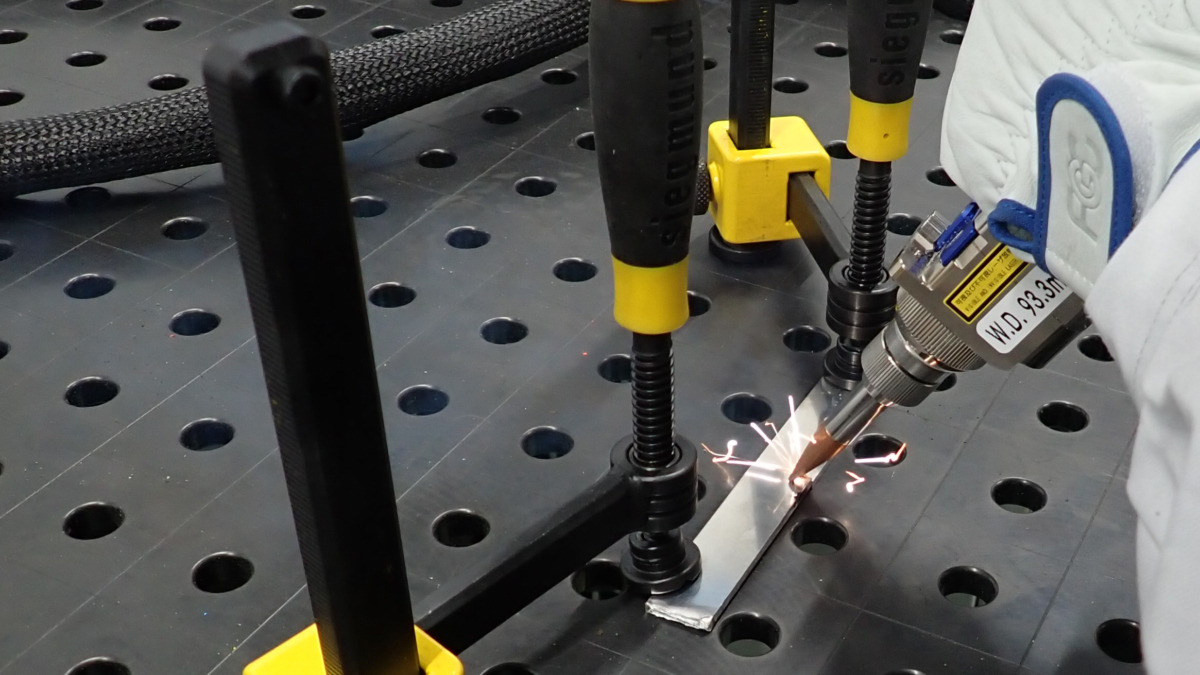

Soldering and joining process

Soldering

Various types of joining such as TIG welding, MIG welding, laser welding, brazing, riveting and cold pressure welding are available.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Arc welding machine | Iron, stainless steel, titanium, aluminum, magnesium Argon gas, carbon dioxide gas |

Manual stick welding, TIG welding, semi-automatic welding | 10 |

| Laser Welding Machine | Thickness 0.5mm to 3mm Output power MAX1000W |

Fiber laser welding with swing function | 1 |

| Gas welding | Acetylene gas | Welding and fusing | 1 |

Joining

We can process joining of iron, steel wire, and nonferrous wire by butt welding (heating and pressure welding). We manufacture electric wire materials such as aluminum as a material processing with high joint strength for metal wire and wire materials.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Heated welding machine (Butt welder) |

φ7mm - φ13mm | ― | 1 |

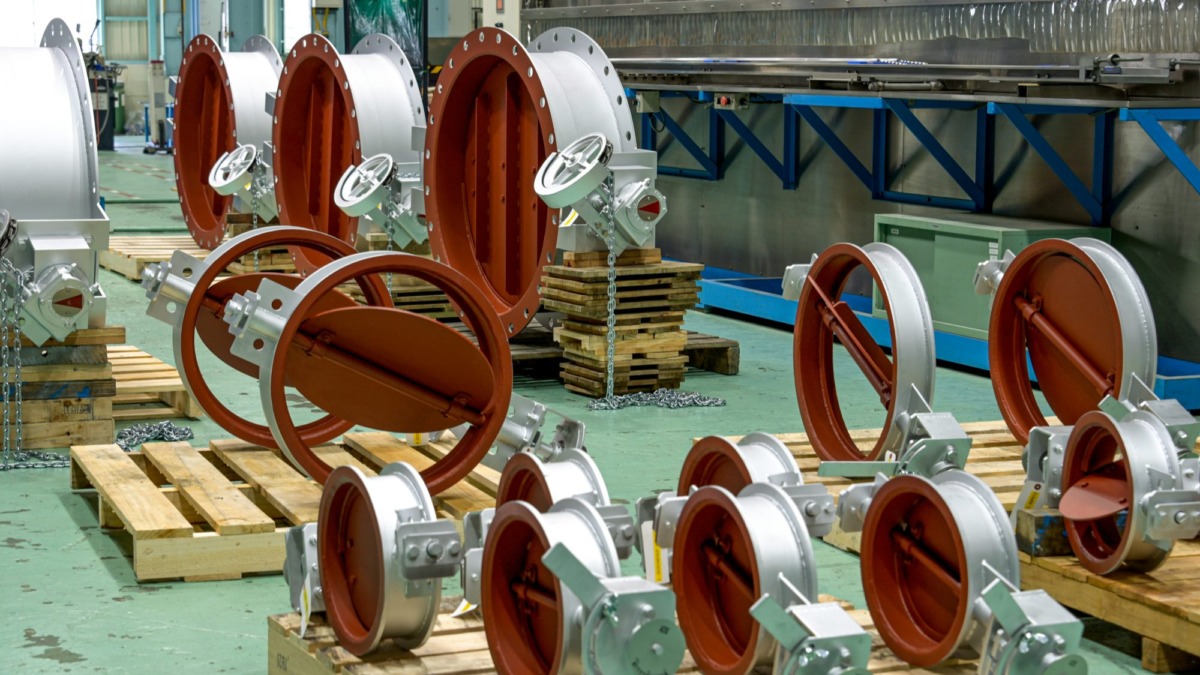

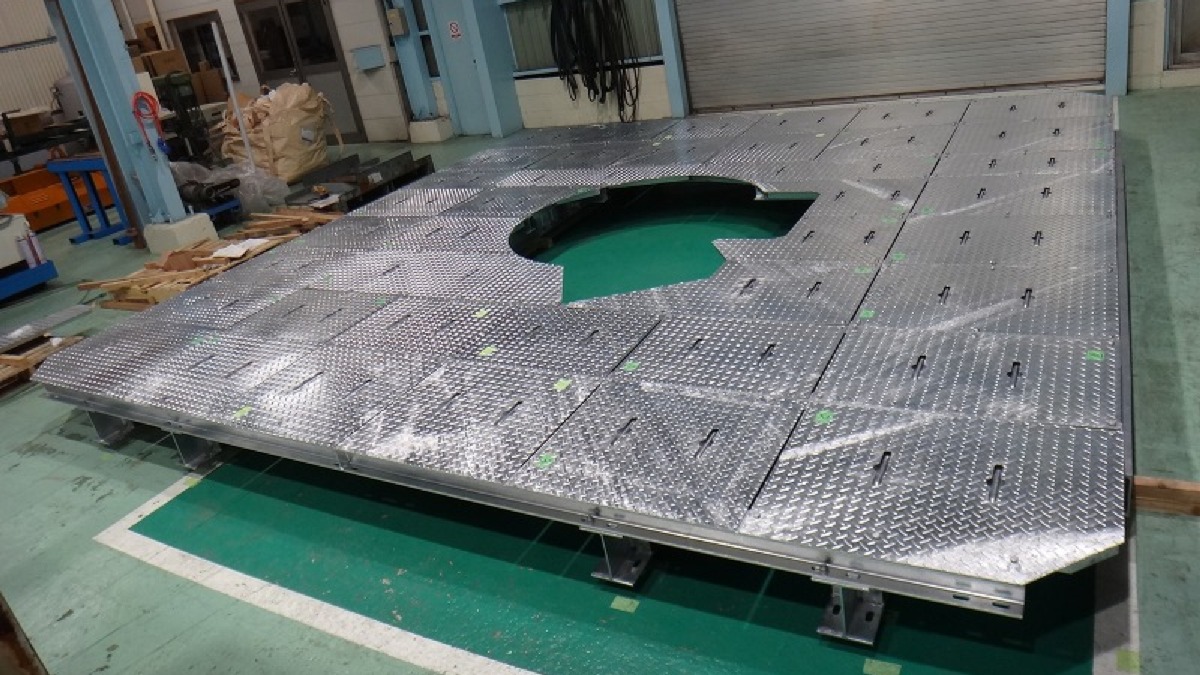

Can manufacturing and Industrial plant products

We manufacture processed products for industrial plants, such as dampers, and processed aluminum cans for various containers. We can process large to precision products regardless of size or material.

We manufacture aluminum alloy cable cleats (underground wire support materials), which are cable gripping fittings for electric power and communication cables. We process and manufacture lightweight and corrosion-resistant aluminum alloy components based on our many years of experience.

Manufacturing Technology

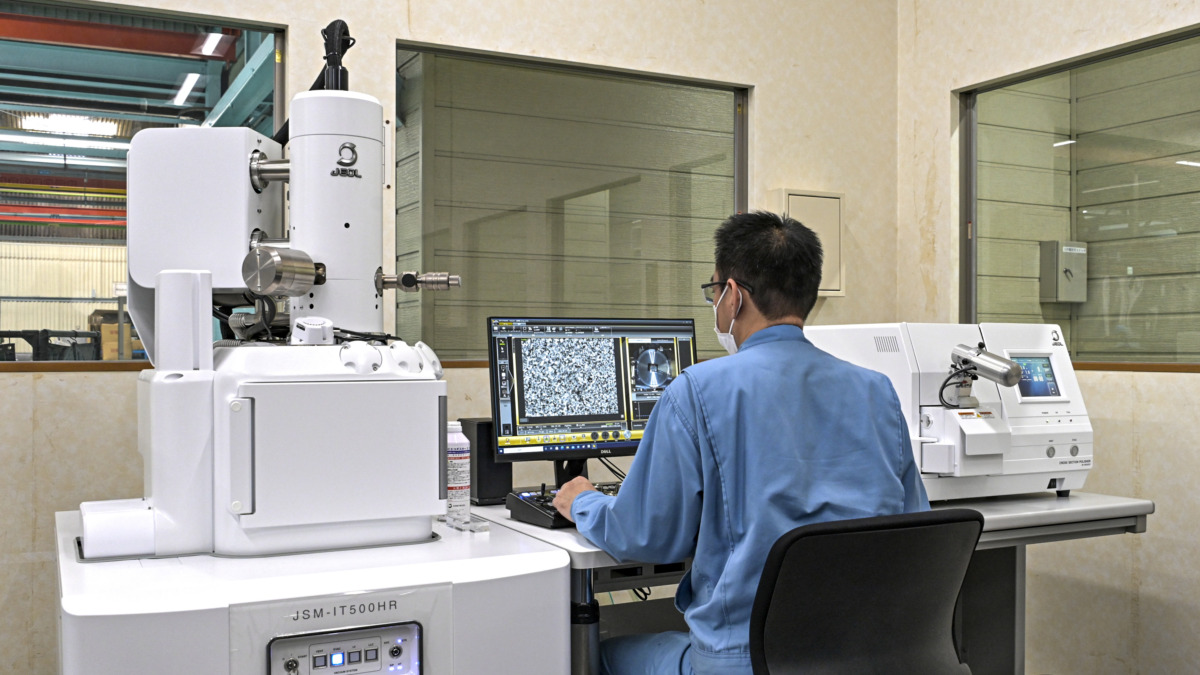

Observational measurement and analytical testing, including eddy current and ultrasonic testing technology

Penetrant Testing PT Level 2 qualified personnel are available for nondestructive testing. Inspection of surface defects by ultrasonic flaw detector is also available. Our quality control department has scanning electron microscope JEOL InTouchScope™ series, various inspection equipment, and inspection technicians in-house, enabling rapid testing - inspection documentation and speedy functional improvement through trial and error in the manufacturing process. We support prototype development to product design, including development of new products and functional improvement of parts.

Click here to see the facilities we have for analysis and inspection equipment.

Design and strength calculations

Communication components (antenna support columns, various types of racks, etc.) We can handle custom-made designs for solar panel installation racks, solar panel mounting girders, etc. We provide design, strength calculation, welding, and plating services for equipment racks for factories and plants such as cubicles, electrical equipment, and mechanical equipment.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| 2D CAD | AutoCAD | CADPAC Design Support |

4 |

| 3D CAD | SOLIDWORKS | 3D drawing support | 1 |

| CAD/CAM | OneCNC | High precision and high efficiency in machining | 1 |

Assembly and temporary assembly

3D Measurement

Introducing the Quantum Max FaroArm portable coordinate measuring machine. Highly accurate and rapid laser 3D scanning contributes to quality assurance of complex geometries.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Quantum Max FaroArm | Contact measurement accuracy: 0.032mm Non-contact measurement accuracy: 0.046mm |

Portable Coordinate Measuring Instruments | 1 |

Processing of long metals

Degreasing and cleaning agent recovery and reuse

We are capable of automatic cleaning of precision parts, large parts, and long parts, and use it to improve the quality of mass-produced and processed products.

We are committed to maintaining the quality of cleaning solutions and collecting and reusing cleaning agents used in degreasing cleaning as an environmental measure.

Equipments

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Degreasing and washing machine | W400mm × H300mm × 6m tank | Steam cleaning, immersion cleaning | 3 |