Clad Metal Materials

Clad material (clad metal) is made by joining dissimilar metals. By combining metals of different properties it acquires unique characteristics that cannot be maintained with one material. By this way, we can enhance functional properties of product components such as weight reduction, corrosion resistance, and control thermal expansion coefficient.

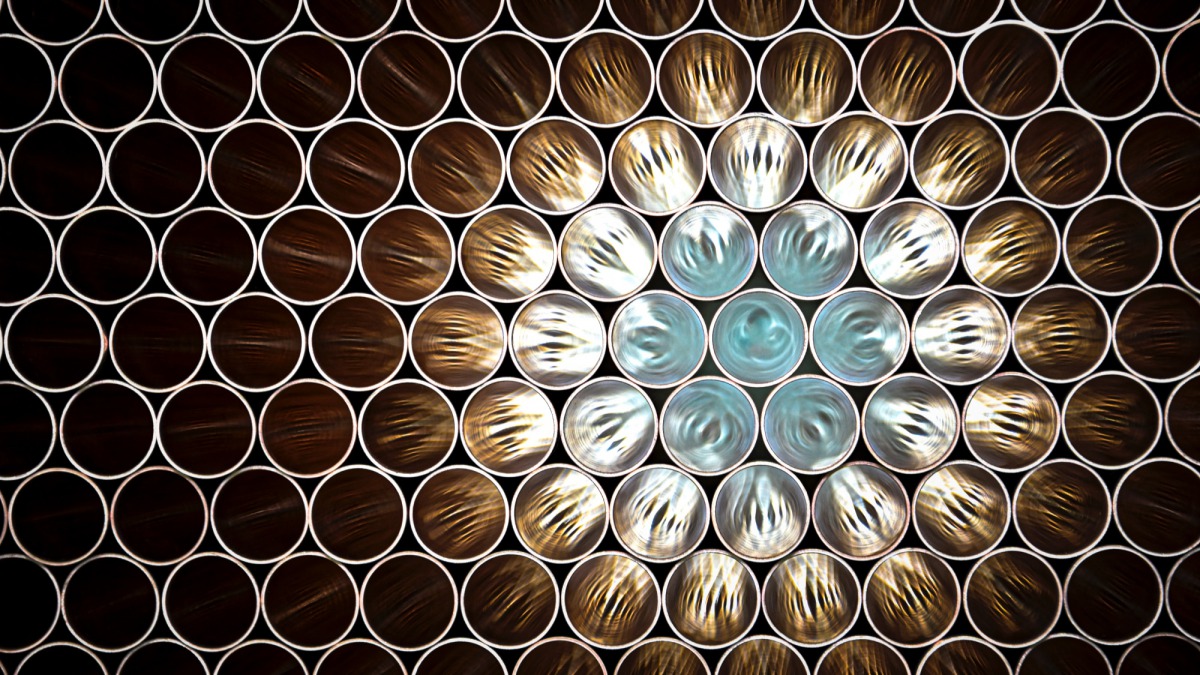

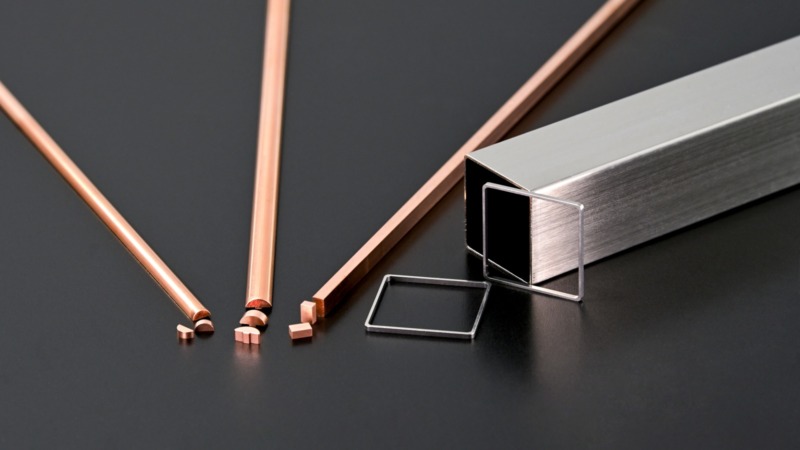

We has long been working on manufacturing metal clad pipes and clad hollow bars with high dimensional accuracy by cold drawing, and is characterized by the technology that joins materials very strong such as diffusion bonding. In addition, various cross-section shapes can be produced, from round-bar shapes to pipes and irregular-shape materials, and the ratio of cross-sectional area can be changed freely using our own method so as to meet all requirements and challenges of its customers.

Some tips for useful combination of functional characteristics of clad materials

● Conductivity x Lightweightness ● Strength x Conductivity

● Corrosion Resistance x Lightweightness ● Thermal Conductivity x Strength

● Magnetic Property x Conductivity ● X-ray Opacity x Conductivity ● Biocompatibility x Strength

Types and applications of clad rods and wires

| Usage | Material | Properties | |

|---|---|---|---|

| Outer | Core material | ||

| Plating electrode | Titanium | Copper and Aluminum |

Corrosion resistance x Electrical conductivity |

| Electrode for refining |

Stainless Steel and Titanium |

Copper and Aluminum |

Corrosion resistance x Electrical conductivity |

| Dumet Wire | Copper | Ni Alloy |

Conductivity x Strength |

| Lightning Rod | Copper | Carbon Steel |

Conductivity x Strength |

| Voice coil | Copper | Aluminum |

Conductive x Lightweight |

| Washer | Carbon Steel | Aluminum |

Strength, weldability x light weight |

| Spring | Carbon Steel | Stainless steel, Copper |

Strength (Spring) x Conductivity |

| Glass hermetic terminal | Carbon Steel | Ni alloy, Copper |

Low thermal expansion x Conductivity |

Types and applications of clad tubing

| Equipment | Material | Fluid | ||

|---|---|---|---|---|

| Outer tube | inner tube | Outer | inner | |

| Ammonia Condenser | Low carbon steel | Copper and copper alloys | Ammonia | Water |

| Oil refinery | Low Carbon Steel | Copper | Oil | Water |

| Coke Cooler | Low Carbon Steel | Copper and Copper Alloys | Naphthalene, etc. | Water |

| Pump piping | Low carbon steel | Copper alloy | Air or Soil | Water |

| Ammonia Condenser Chillers | Copper and copper alloys | Low carbon steel | Water | Ammonia |

| Scientific Condensers | Stainless Steel | Cupronickel | Chemicals | Water |

| Beverage, cosmetics, medicine, food, plastic industry, etc. |

Aluminum or Stainless Steel |

Copper or copper alloy | Raw materials | Water |

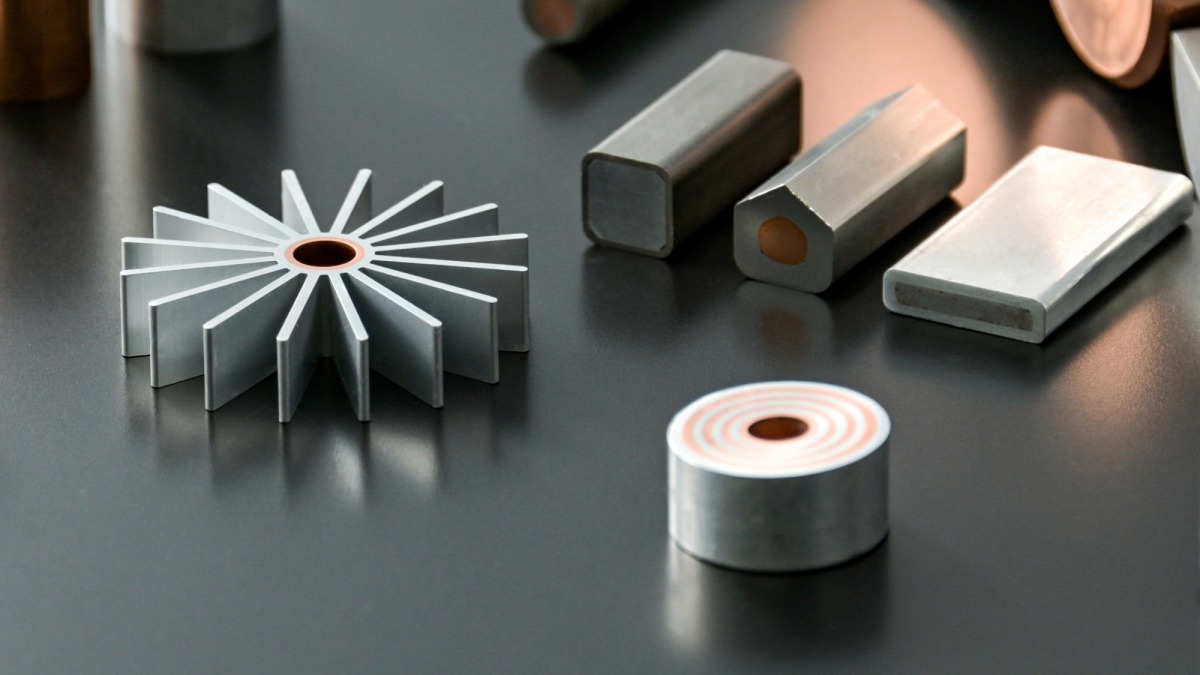

Various shaped clad tube and bar / Metal composite material

Development of new components and functional materials with multi-layer clad pipes

Multi-layer clad hollow bar materials are constructed with two or more layers, adding more complex functions. Utilizing various processing technologies such as joint adjustment of specially shaped multi-layer clad pipes, heat treatment, cutting, and bending, we handle everything from manufacturing to analytical tests that requires high level of in-house technology. We promptly respond to our customers’ requests, from material development, product design of new materials, to solving problems of existing materials.

Biocompatible materials for medical use (cobalt alloys, titanium, stainless steel, etc.) thin-walled pipes/clad wires

Cobalt alloy pipes (MP35N/L605/Elgiloy) clad wires/thin-walled pipes for medical catheters and other applications are widely used in electronic components for medical purposes. We prototype, develop, and manufacture small-diameter clad wires, clad rods/clad wire materials, and highly biocompatible metallic biomaterials.

Composite materials with infinite potential for solving complex challenges

Clad materials combine materials with specific functions to achieve properties impossible with a single material. Leverages our unique pipe, bar, and wire processing technologies and expertise cultivated over many years to provide high-quality clad materials that meet all customer needs. We do more than simply combine materials. As specialists in material fusion, we maximize the inherent properties of each material to create new value, constantly pursuing the cutting edge of technology.

| Outer Shell | |

|---|---|

| Corrosion Resistance | Stainless Steel, Titanium, Nickel, Tantalum |

| Heat Resistance | Stainless Steel, Tantalum |

| Mechanical Strength | Piano Wire Stainless Steel, Various Heat-Treated Alloys |

| Electromagnetic Shielding | Aluminum |

| Biocompatibility | Cobalt Alloy, Titanium Alloy |

| Magnetic Properties | Permalloy and Other Magnetic Alloys, Various Coils |

| Weight Reduction | Aluminum |

| Complex Shapes | Aluminum Extruded Profiles |

| Catalyst | Platinum |

| Electrical Resistance | Nichrome, Manganin |

| Shape Memory | Titanium Alloy |

| Thermal Expansion | Kovar, Invar |

| Mechanical Strength | Electromagnetic Shielding |

| Biocompatibility | Magnetic Properties |

| Weight Reduction | Complex Shapes |

| Catalyst | Electrical Resistance |

| Shape Memory | Thermal Expansion |

| Core Materials | |

|---|---|

| Conductivity | Silver, Copper, Aluminum |

| Vibration Absorption | Rubber, Resin, Magnesium |

| X-ray Transparency | Tantalum, Platinum |

| Fluid | Air, Vacuum, Magnetic Fluid |

| Magnetic Properties | Magnetic alloys such as Permalloy, Various coils |

| Mechanical Strength | Piano wire, Stainless steel |

| Shape Memory | Titanium alloy |

| Communication | Optical fiber |

The Future Unlocked by Clad Materials

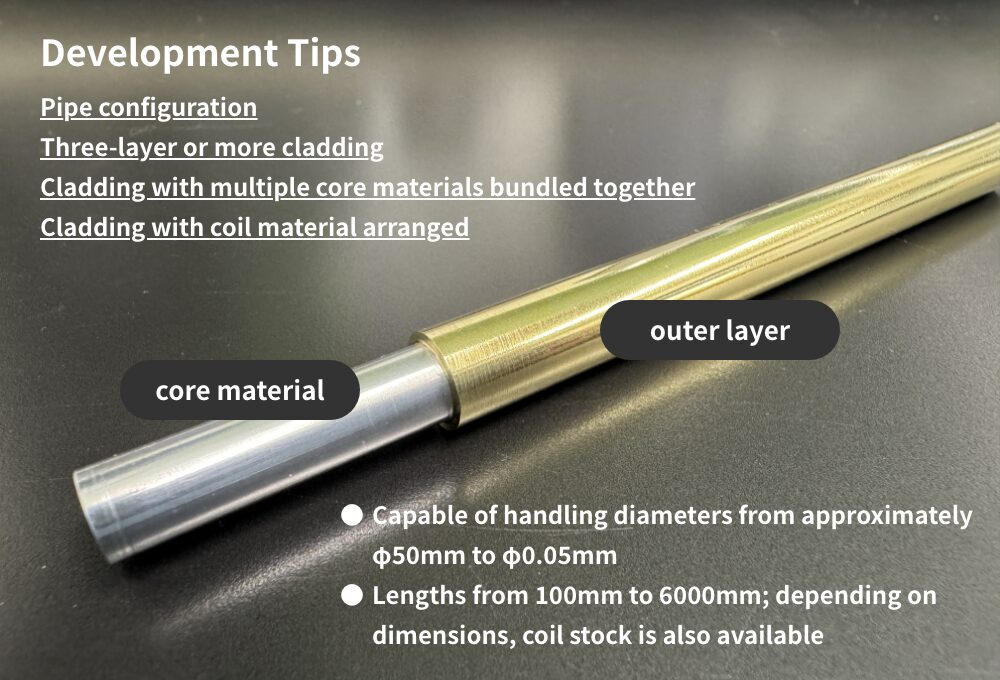

Research and Development Tips

Clad materials hold infinite potential through their combinations. Below, we present specific application examples to inspire engineers and researchers, along with the possibilities we can offer.

1Corrosion resistance and high strength

Enhanced performance in harsh environments

Hints for solving challenges

Corrosion issues in seawater and acidic environments, maintaining strength under high temperature and pressure.

Application Examples

Offshore structures, chemical plant piping, heat exchangers, flue gas desulfurization equipment.

Our Potential

Combining corrosion-resistant materials (e.g., titanium, stainless steel, nickel alloys) with structural materials (e.g., carbon steel, high-tensile steel). Achieving weight reduction through cladding technology and thin-walled designs, while selecting optimal materials tailored to specific corrosion environments.

2Optimizing thermal conductivity

Highly efficient energy use

Tips for solving problems

Improved thermal efficiency, suppression of thermal runaway, and improved heat dissipation.

Application Examples

Fuel cells, heat dissipation parts for EV batteries, heat sinks for LED lighting, and high-efficiency boilers.

Our Potential

Combining high thermal conductivity materials (e.g. copper, aluminum) with high strength materials (e.g. stainless steel). Precise control of thermal conductivity characteristics according to your needs. Handling complex shapes and processing technology.

3Adding different functionality

Creating new value

Tips for solving problems

We want to provide multiple functions at the same time, such as antibacterial properties, electromagnetic wave shielding, design, and biocompatibility.

Application Examples

Medical equipment, food processing equipment, electronic components, building materials, design products.

Our Potential

Combining functional materials (e.g. antibacterial copper, electromagnetic wave shielding materials, precious metals) with practical materials. Development of high-value-added clad materials combined with surface modification technology. Supporting small-lot, high-mix, and custom-made production.

4Sensor applications

Highly accurate and durable sensing solution

Tips for solving problems

Highly sensitive magnetic detection, noise suppression, stable operation in harsh environments, and compact size.

Application Examples

Magnetic sensors, current sensors, non-contact switches, encoders, security devices.

Our Potential

Combining magnetic alloys (e.g., permalloy, amorphous alloys, ferritic stainless steel) with non-magnetic materials (e.g., non-magnetic stainless steel, copper alloys). Improved detection accuracy and noise resistance are both achieved. Improved environmental resistance (heat resistance, corrosion resistance) extends the life of the sensor. Cladding with materials that have specific magnetic properties (high permeability, low coercive force, etc.) contributes to the development of high-performance sensors.

5Post-processing of the above clad materials

After the clad material is made, we also provide one-stop support for post-processing such as cutting, drilling, bending, welding, straightening, and surface treatment.

Tips for solving problems

Highly sensitive magnetic detection, noise suppression, stable operation in harsh environments, and compact size.

We can handle prototypes and small lots

We can flexibly accommodate prototyping at the idea stage and small-lot production for research and development purposes.

A combination of a wide variety of materials

In addition to different metals, we also consider compounding with ceramics and resins upon request.

Promoting joint development

As your research and development partner, we will work together to create optimal solutions.

Comprehensive Clad Electrode Processing Services

Electrodes essential for electrolytic refining and plating

Clad materials achieve the dual properties of corrosion resistance and electrical conductivity—difficult to achieve with a single material—by bonding different metals together.

Kansai Pipe provides comprehensive support from manufacturing this clad material to achieving the final electrode shape our customers require. Rather than designing electrode performance—such as electrical and chemical specifications—from scratch, we respect our customers' expertise and preferences, collaborating to create the optimal product. Even without detailed drawings, we carefully listen to sketches and ideas at the conceptual stage, proposing the best manufacturing methods as processing professionals.

Our strength lies in our ability to bring your concepts to life. We can handle not only round shapes but also square and irregular cross-sections, with particular expertise in producing long clad materials. For round shapes, we accommodate outer diameters from approximately 10mm to 60mm and lengths up to about 4000mm. We can combine diverse materials such as titanium, copper, and iron, and also accept processing using materials supplied by the customer. Our products have been utilized across various fields, including seawater electrolysis, electropolishing, nickel and zinc electro-refining, and anodizing. We provide a one-stop solution covering everything from manufacturing to welding, end sealing, cutting/drilling, and surface plating. For high-quality clad electrodes, please entrust Kansai Pipe.

Materials Processing

- Cold drawn

- Metal shaving

- Swaging process

- Metal straightening

- Correction

- Heat treatment

- Solvent degreasing process

- Polishing

Functional

- Quality stable

- Thermal conductivity

- Thinning out

- Thinning

- High dimensional accuracy

Industrial fields

- Medical equipment

- Electrode