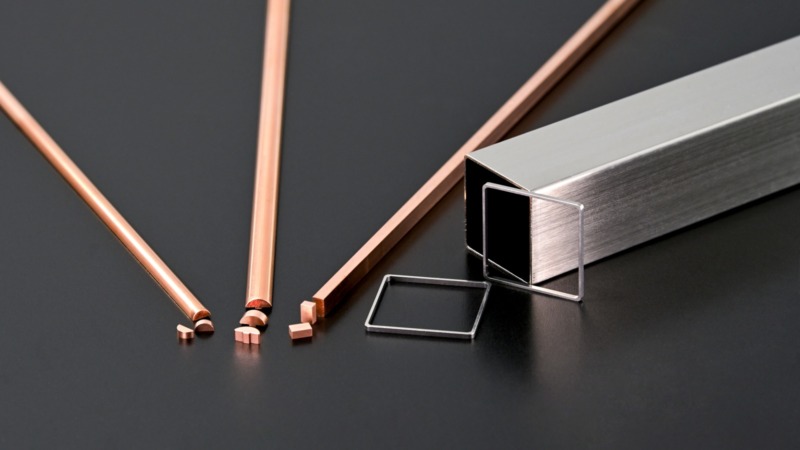

Long twist processing (torsion/twist) and spiral processing industrial parts manufacturing

We can manufacture long twist processing and spiral processing pipes, fins, screw conveyor parts, etc. up to 10m in length. For screw-shaped long parts that twist long plates and deformed bars, etc. at precise pitch, we can adjust the number of twist cycles, design, manufacture, and propose composite products combined with various metal pipes such as clad pipes, irregularly shaped pipes, etc. We can handle everything from prototype development to customization to meet your orders.

Fluid equipment parts such as gas and powder, spiral parts, screw conveyors, etc., manufactured from prototype development with long twists up to 10m.

Composite parts of spiral tubes, inner fin tubes, and twisted rods are used for fluid equipment parts (rectification, degassing, and air intake, such as spiral heat exchangers in thermal power plants), rotating and moving powder conveying equipment (food factories, garbage incinerators, screw conveyors, etc.), heat transfer tubes, spiral fin tubes (aerospace parts), and construction materials (design of twisted shapes/airflow measures). We can develop and custom-manufacture fluid piping components and fluid pipeline components for industrial plants to suit a wide variety of transfers and functions, mainly in steel, stainless steel, aluminum, and copper, such as construction materials (twisted shape design and air ventilation measures).

Design and manufacture of long fin tubes and twisted tubes from prototypes by combining complex deformed wire and plate processing and pipe

For screw-shaped long parts that twist plates and bars at a precise pitch, we can design, manufacture, and propose twist-processed parts and spiral tubes that utilize various shapes in a composite manner based on our long plate processing technology and our technology cultivated through our experience in manufacturing and processing a wide variety of metal tube and bar products.

Equipment

| Equipment name | Specifications | Uses and Features | Number of machines |

|---|---|---|---|

| Twisting | Up to 10m | Twist processing mass production machine Capable of twisting at equal pitch and equal intervals | 1 |

Uses and Features

| Uses | Feature | Metal name | Materials, Standard name |

|---|---|---|---|

| Fluid transfer equipment piping | Supports prototype development of fin shapes from sheet materials | Aluminum, Stainless steel, Copper, Steel, etc. | ― |

Materials Processing

- Metal stamping

- Long materials

- Cold drawn

- Swaging process

- Cutting process

- Polishing

- Metal shaving

- Bonding material

Functional

- Running cost reduction

- Design

- Heat resistance

- Thermal conductivity

- Manufacturing cost reduction

- Corrosion resistance

- Material cost reduction

- Thinning

- Weight saving

- Heat dissipation

- High strength

- Inspection cost reduction

- Mass production

- Chemical resistance

- Thinning out

Industrial fields

- Air conditioner

- Industrial plants

- Environmental energy

- OEM and ODM

- Heat exchangers

- Semiconductors

- Medical equipment