Precision Pipe and Tube Fabrication

We manufacture various types of specially processed products that have been bent, drilled, and machined, as well as conductive/electrical materials such as titanium, which is difficult to process as a difficult-to-cut material. To meet our customer needs, everything from individual production of prototypes to material manufacturing and processing is provided.

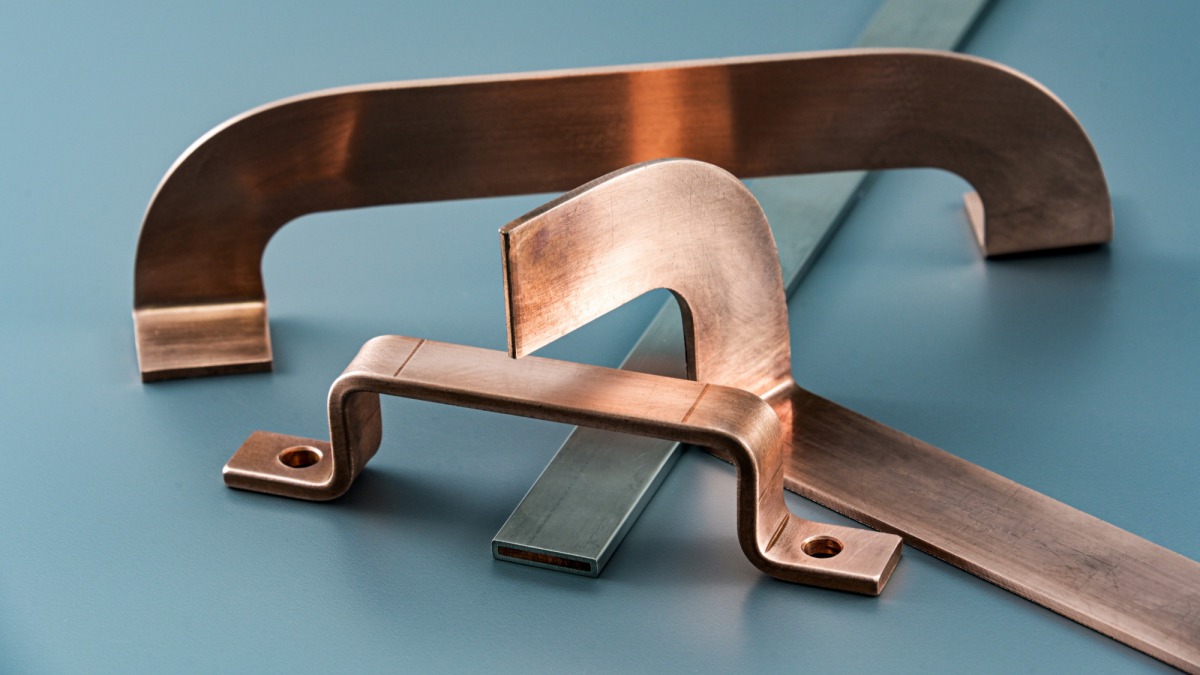

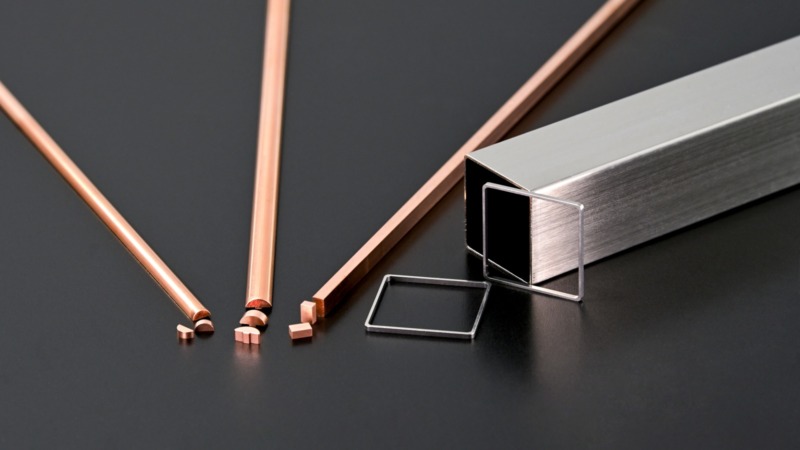

Busbar (copper / aluminum / clad material)

We produce conductive materials such as bus bars in the desired size, using copper and aluminum plate materials, with various bending processes, such as flat-wise bending, edgewise bending, and spiral processing. We support material manufacturing, various secondary processing such as bending, perforation and machining, as well as individual prototyping of products.

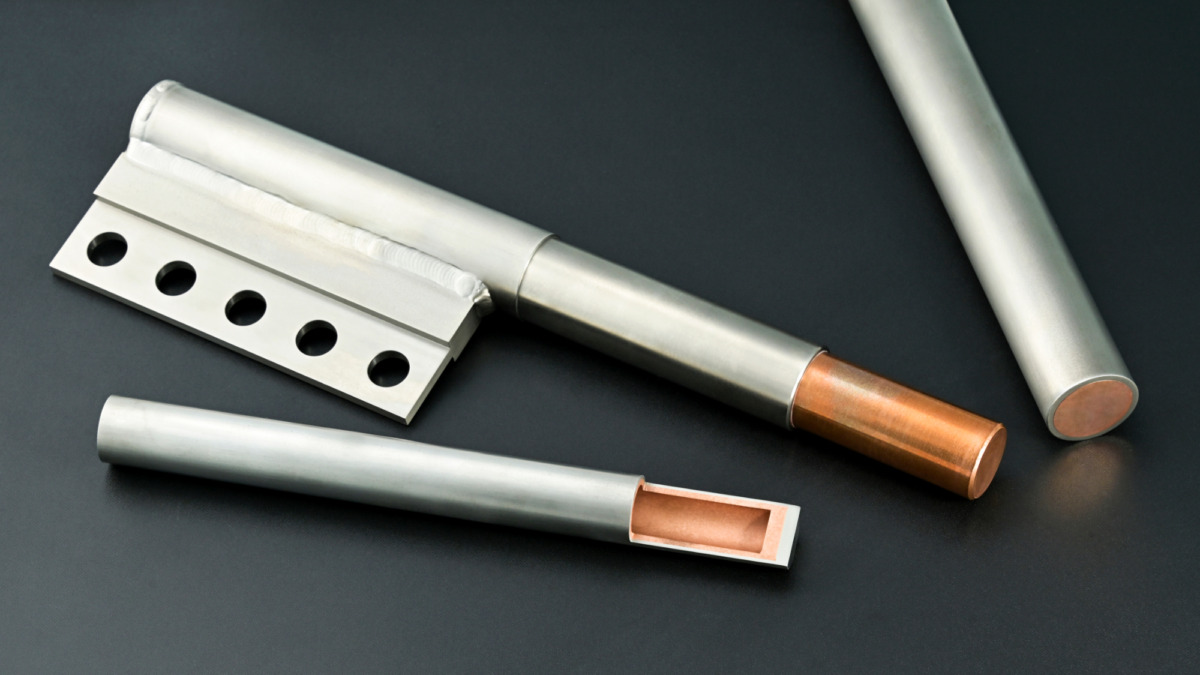

Titanium clad electrode

We manufacture titanium-clad tubing bar and pipe materials made of lightweight and highly corrosion-resistant titanium with dissimilar metals/special metals such as copper alloys, aluminum alloys, and stainless steel. We combine our drawing and welding technologies with machining technology to provide titanium clad electrodes of various shapes to meet your specifications. The ratio of cross-sectional area can be adjusted freely by our original processing technology.

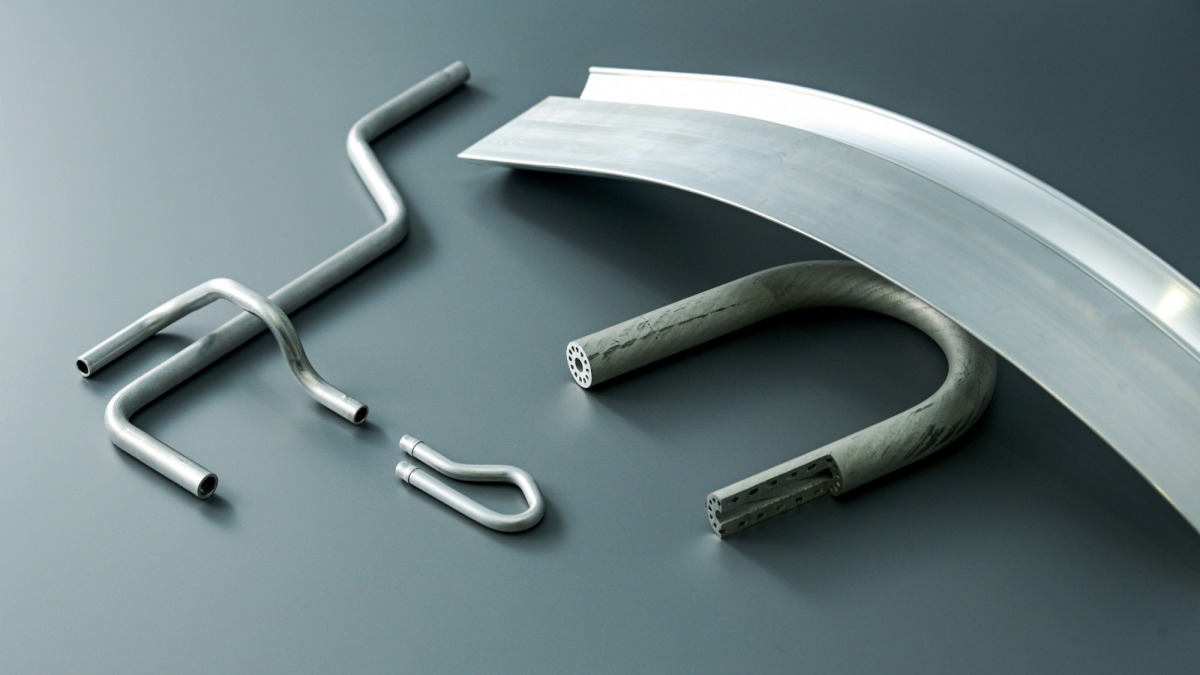

Bending pipe product

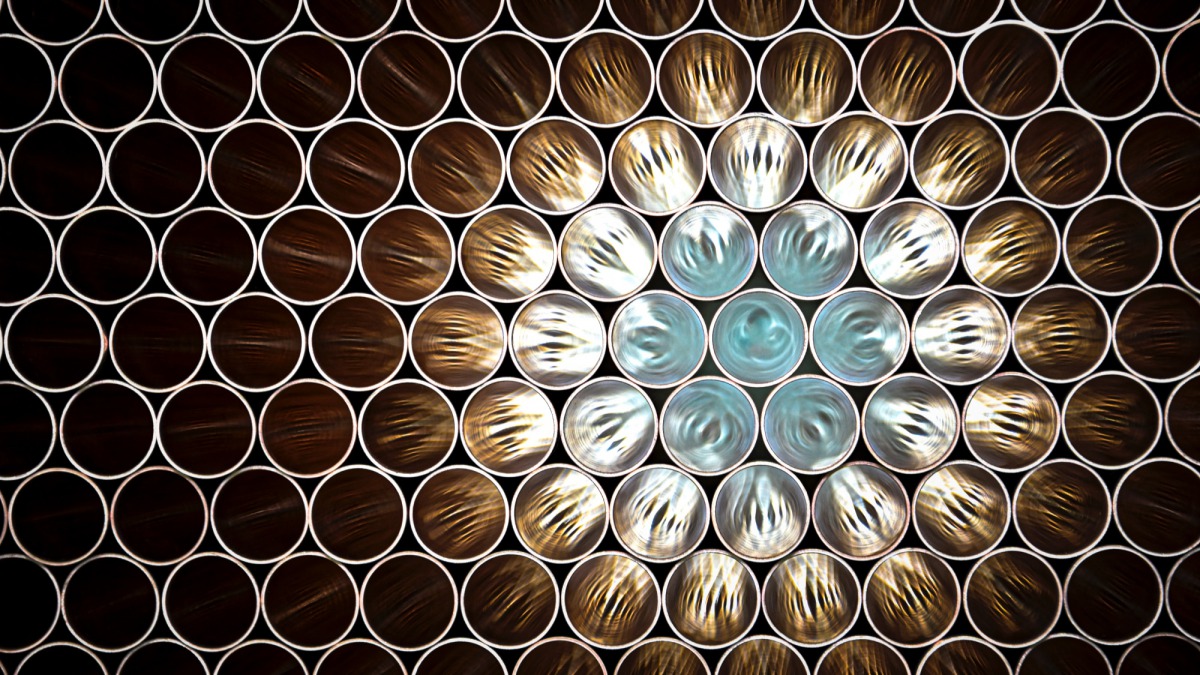

Long twisted fin tube for heat exchanger

We can manufacture twisted pipes and fin tubes from bars, wires, extruded materials, and plate materials ranging from 100 mm to max. 10 meters. We can also produce long tube and bar materials of non-ferrous metal such as copper alloy/aluminum alloy fin tubes and various heat exchanger members with excellent corrosion resistance and lightweight properties, with machining capacity of up to 5 meters.

Materials Processing

- Bending process

- Drilling

- Cold drawn

- Metal shaving

- Bonding material

- Swaging process

- Precision machining

- Metal straightening

- Correction

- Cutting process

- Heat treatment

- Solvent degreasing process

- Polishing

Functional

- Stable supply

- Quality stable

Industrial fields

- Industrial plants

- Optical fiber communication

- Electric power hardware

- Electrode

- Heat exchangers

- ICT

- Automotive parts

- Semiconductors

- Medical equipment