Aluminum alloy processing

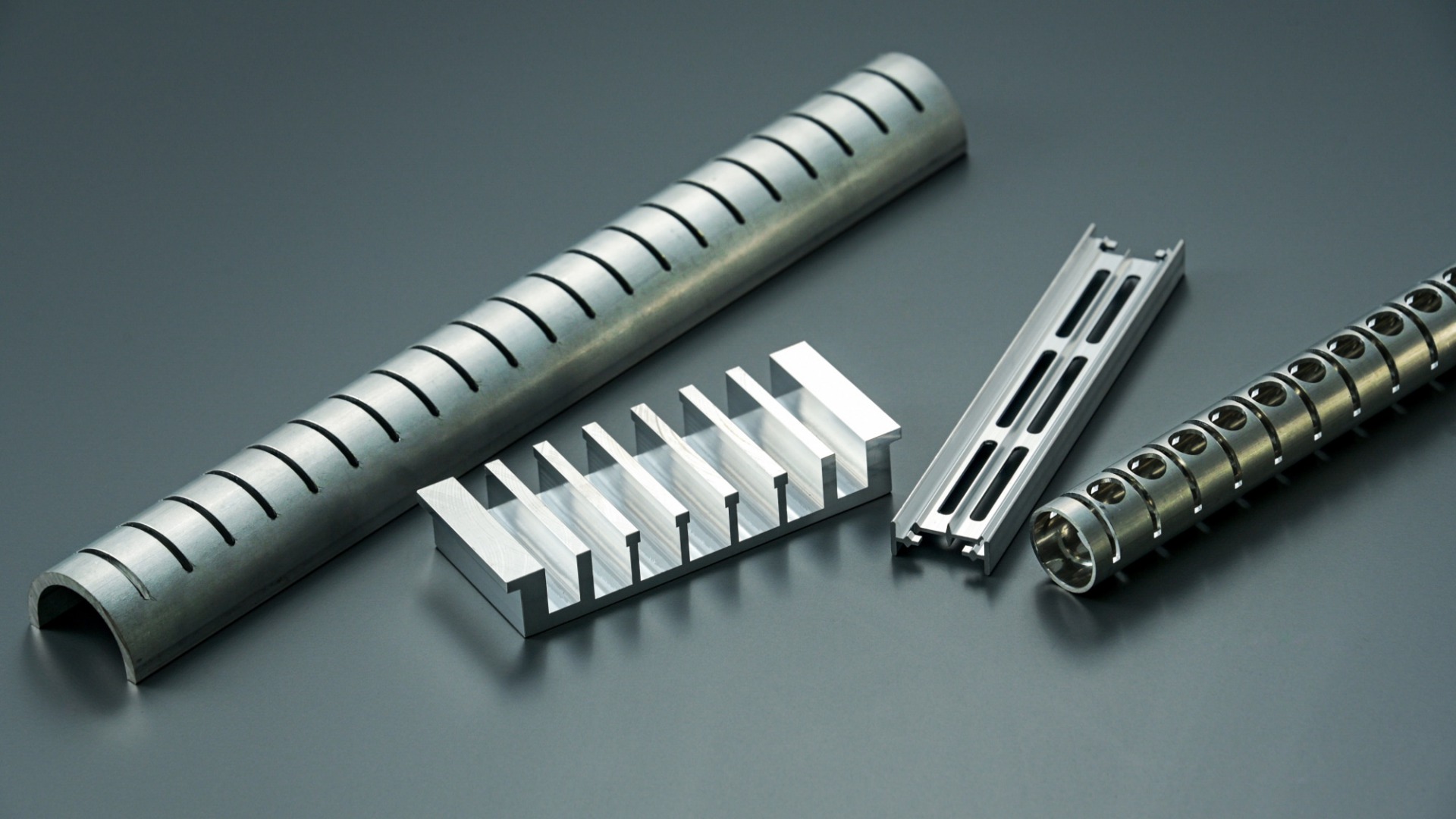

We produce aluminum/aluminum alloy-based materials by unique bonding art that combines welding and plastic working technologies. We work on machined parts of aluminum alloy with complicated shapes and high functionality such as fin tubes with inner groove and twisted fin pipes.

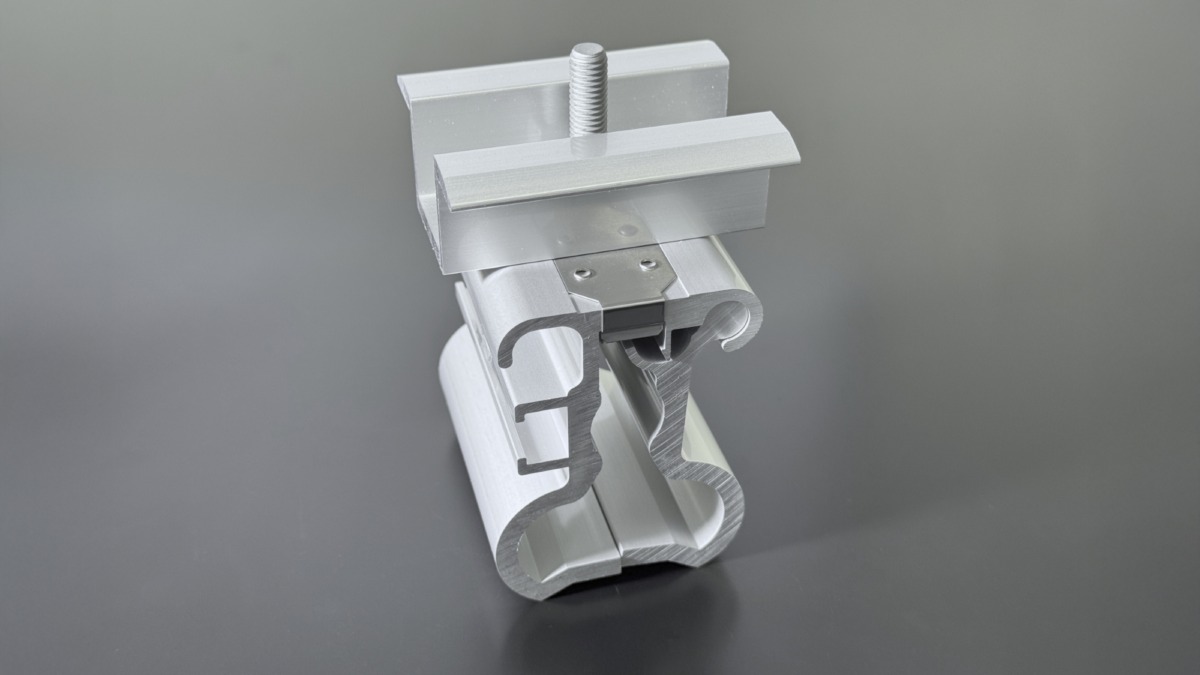

Aluminum alloy cleat

We produce aluminum alloy cable cleats, which are cable holding fittings for electric power and communication wires. We provide lightweight, highly corrosion-resistant materials and support electric power and communication infrastructure with our decades-long experience. A wide variety of cable sizes are available.

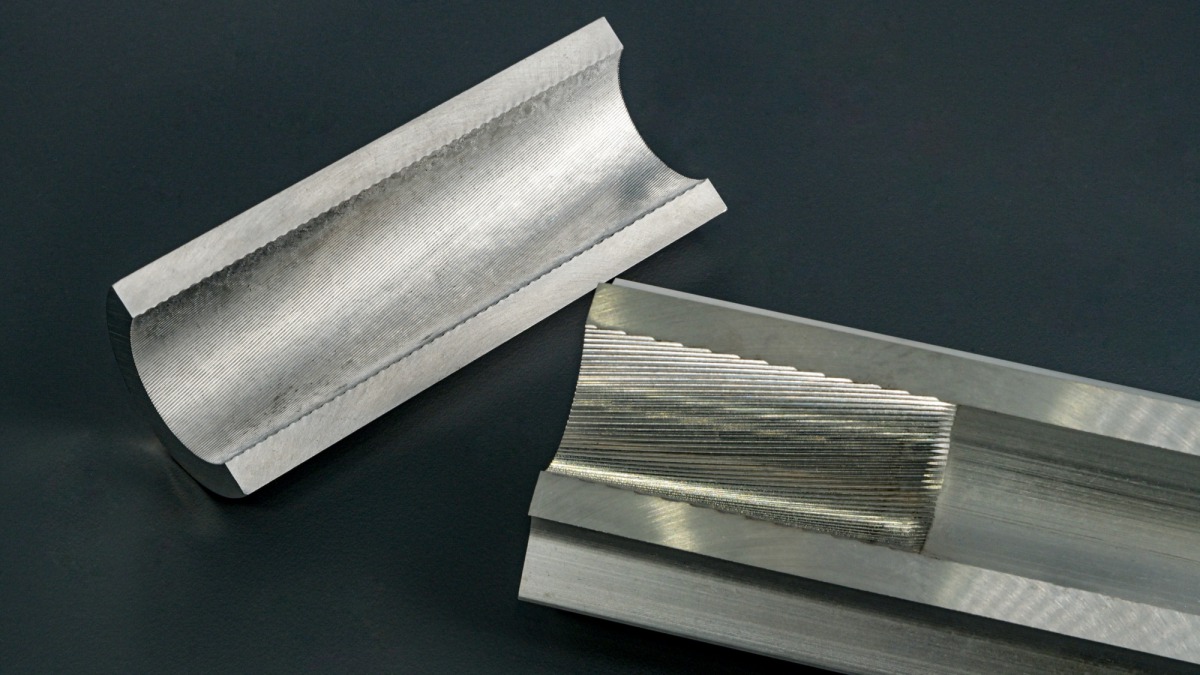

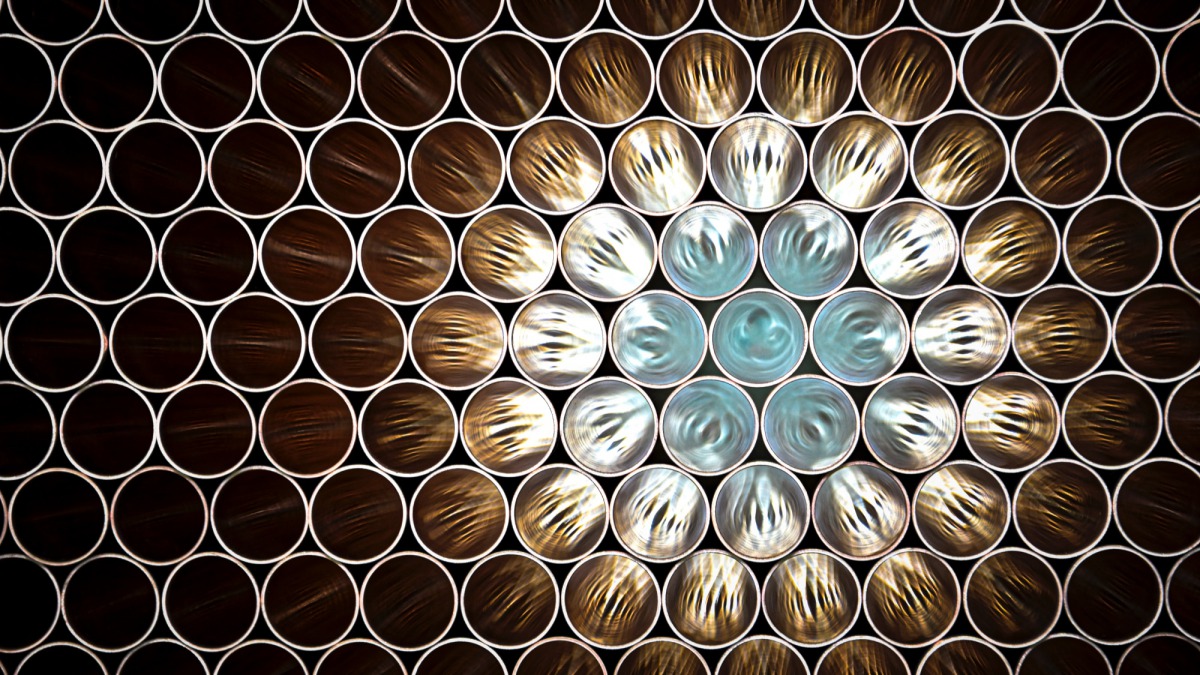

Inner grooved tube (fin tube)

We manufacture fin tubes of copper/copper alloys, aluminum alloys and various metals, along with pipe materials and heat exchanger parts, etc., which are characterized by their complicated cross-sectional shapes. We are also able to deal with irregular-shape pipes and multifoil-shaped pipes as well as various inner surface shapes such as fin tubes that have inner grooves by special processing. Therefore, we can respond to customers’ request with our own technology. Since we are able to process straight and spiral grooves on inner grooved pipe materials (fin tubes), we will be very much pleased if we can contribute to your effort to improve thermal efficiency.

Long-length twist processing/Spiral processing

Aluminum alloy fin pipe/bar

It is possible to twist tubes, bars, plates and forms whose sizes vary from 100 mm to up to approx. 10 meters. When twisted, the heat exchange efficiency of the material is usually expected to improve due to increase of the surface area, or that turbulence in the flow path can be generated. We make functional materials for various heat exchangers, such as aluminum alloy fin tubes which are highly corrosion resistant and lightweight.

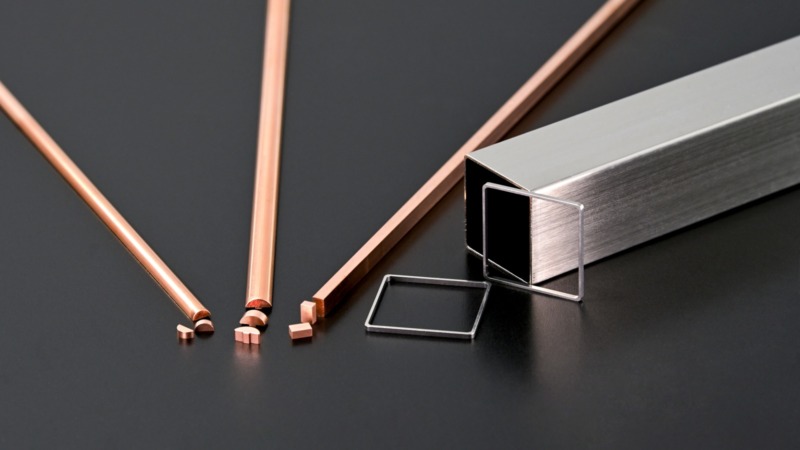

Aluminum extruded material processing

Please let us manufacture your extruded aluminum alloy products from material procurement to final products. We create desired cross-sectional material and carry out the cutting, hole making, pressing, welding and degreasing process, managing everything from designing to manufacturing and inspection.

Materials Processing

- Drilling

- Bonding material

- Metal stamping

Functional

- Quality stable

- Design

- Corrosion resistance

- Weight saving

- High strength

- Mass production

Industrial fields

- Electric power hardware

- Heat exchangers

- Automotive parts

- Air conditioner