Trolley Bus Bar

Industrial trolley systems are widely used as feeders for transport devices such as cranes and hoists in factories. We have a lineup of both rigid and insulated trolleys, so as to be feeders with specifications suitable for the environment. Quite a large number of trolleys have been delivered to fit in cranes and others of general factories, steelworks and shipyards, and highly appreciated.

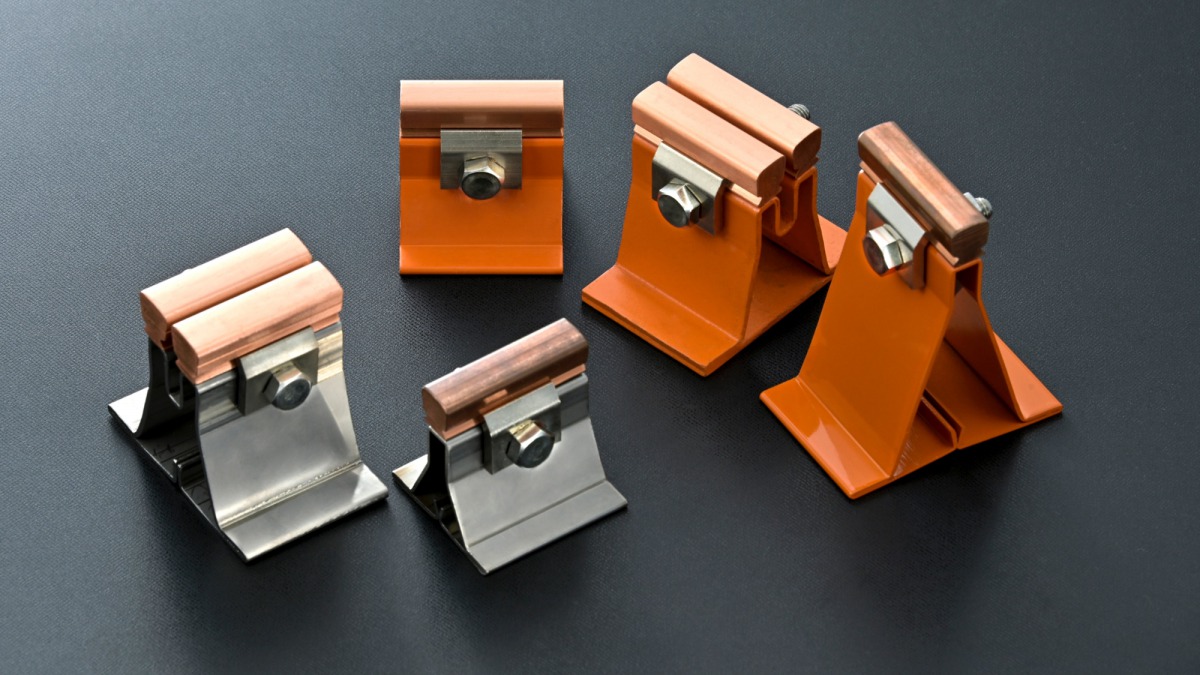

Industrial rigid trolley system

- A unit-type power feeder that has excellent mechanical strength and can handle large current.

- Tensionless trolley reduces the risk of disconnection.

- There are a wide variety of iron mounts that can be selected from hot-dip galvanized mounts and stainless-steel mounts so that they can withstand corrosive environments.

- Our trolley line can be made of common copper or copper alloy containing silver for high heat-resistance.

Industrial insulated trolley system

- This is the power supply system used for carrying devices at production sites with excellent safety features.

- The conductor is covered with insulation for the entire length, reducing the risk of electric shock.

- Unit type Sumi-Trolley is available in heat-resistant, corrosion-resistant, and high-speed types, and we have a lineup of them from small to large sizes.

- The long-length Sumi-Long C can be installed seamlessly up to 350 meters.

Materials Processing

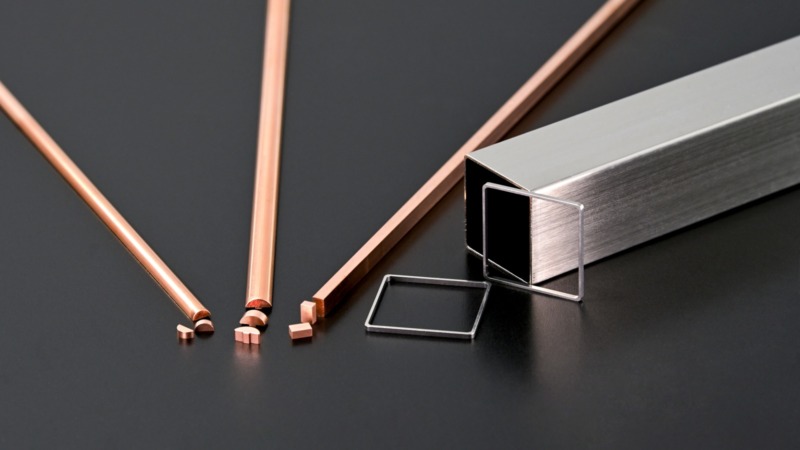

- Cold drawn

- Swaging process

- Metal straightening

- Correction

- Heat treatment

- Solvent degreasing process

Functional

- Corrosion resistance

- Thermal conductivity

- High dimensional accuracy

- Quality stable

Industrial fields

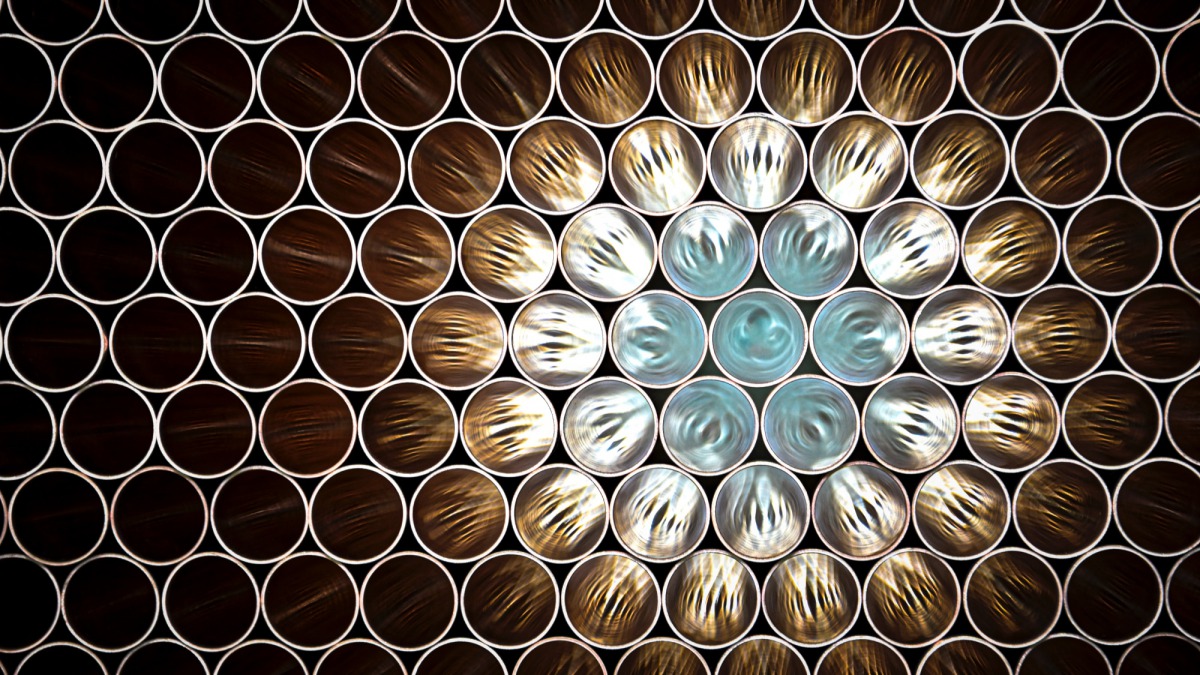

- Heat exchangers