Various shaped Pipe, Tube and Bar

We manufacture irregular-shape hollow bars and special hollow bar products of various metals including copper and aluminum. Utilizing our precision processing technology in the fields of machining and welding, we can propose on various aspects of production from material selection that satisfies required performance to processing and inspection with one-stop-shop operation. We support a wide range of projects from prototyping to mass production.

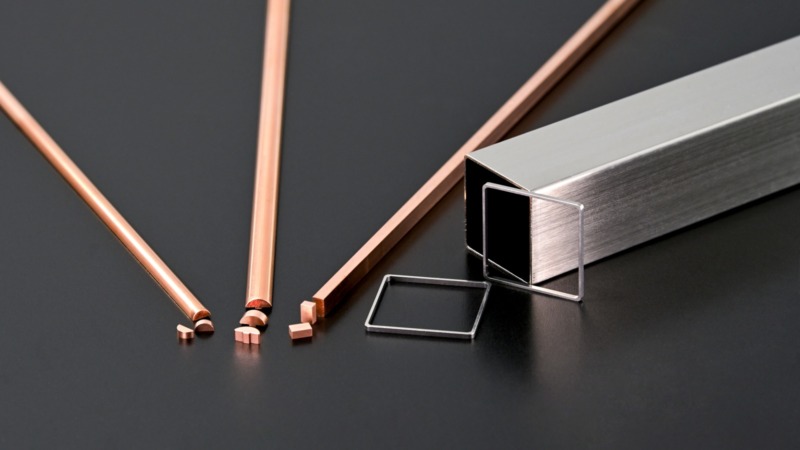

Irregular-shape clad pipe

Irregular shaped clad pipes with unique internal flow paths can be shaped by fitting the same, or different metals to pipe materials. We are able to add special properties that are difficult to achieve with a single material and shape. For example, surface area will increase by twisting the inner material. We consistently support special designing and production of functional materials to solve problems, covering every stages of production from technological development, prototyping to mass production.

Titanium clad bar material, titanium bending process

We manufacture titanium, titanium clad hollow bars and pipe materials made of lightweight and highly corrosion resistant titanium and dissimilar metals/special metals such as copper alloys, aluminum alloys and stainless steel. we are able to supply titanium clad electrodes of various shapes that meet customers’ specifications with our original technology that combines drawing, welding and machining. You can change cross-sectional area ratios freely with our original processing technology.

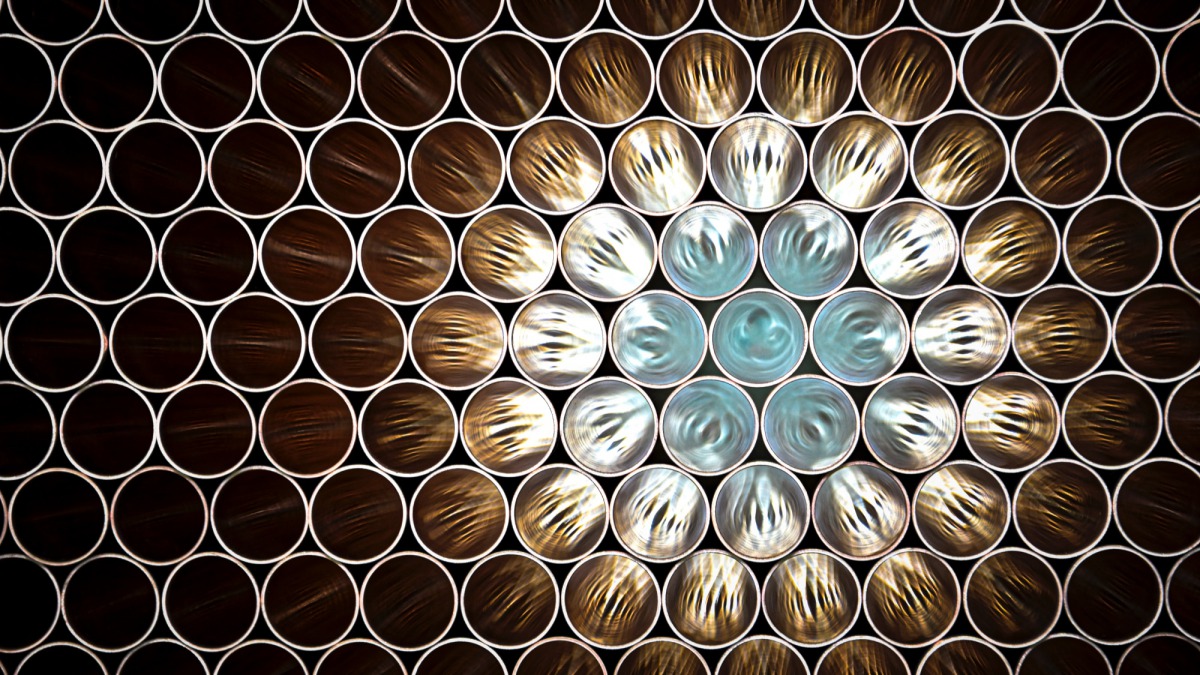

Long material twisting process

It is possible to manufacture pipes and fin tubes by twisting bars, wires, extruded materials, and sheet materials from 100 mm up to 10 meters. We manufacture non-ferrous metal long hollow bar materials such as copper alloy/aluminum alloy fin tubes, various heat exchanger members with excellent corrosion resistance and light weight, for machining up to 5 meters.

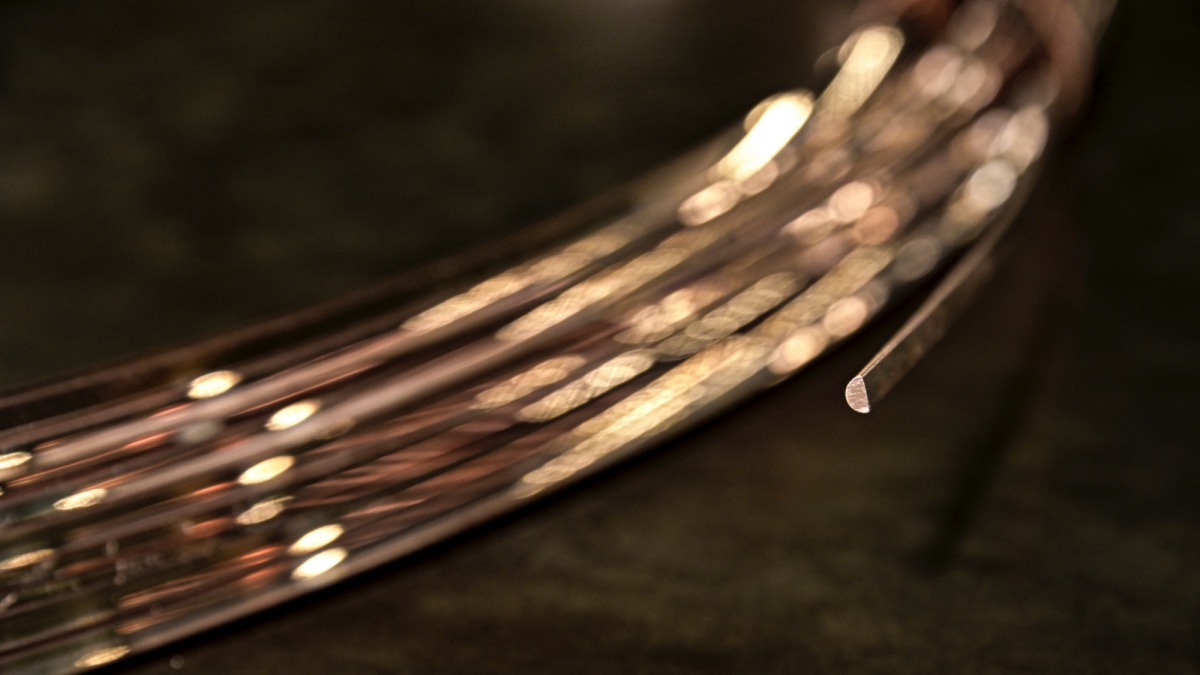

Irregular-shape wire

Using various metals such as copper and aluminum, we manufacture precision metal materials of ultra-fine diameter and irregular shape such as ultra-fine wires and bars up to φ0.05mm by cold drawing. We are able to handle various shapes, such as cross-sectional shapes in polygons or honeycomb hexagon, and support customers’ requests from prototyping to mass production.

Materials Processing

- Cold drawn

- Swaging process

- Heat treatment

Functional

- Electrical conductivity

- Thermal conductivity

- Initial cost reduction

- Manufacturing cost reduction

- Material cost reduction

- High dimensional accuracy

- Quality stable

- Weight saving

- High strength

Industrial fields

- Automotive parts