Kovar Pipe and Tube

Kovar pipes are sealed with hard glasses/ceramics, and are used as main materials for optical semiconductor packages such as semiconductor optical amplifiers, electronic devices (electron tubes, electronic displays), and electronic components. Kovar (Fe-Ni-Co), an alloy of iron, nickel and cobalt, is characterized by its thermal expansion coefficient equivalent to that of hard glass and ceramics.

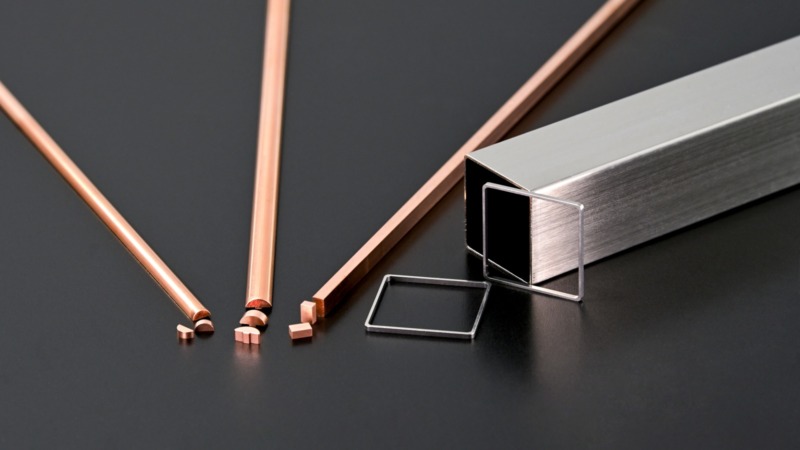

Custom-made conductive products such as seamless Kovar pipes cladded with copper for low thermal expansion are also available.

Kovar properties

| Related Standards | ASTM F15 |

|---|---|

| Characteristics | Matching and sealing with hard glass |

| Volume Resistivity | 48 × 10-8 Ω - m |

| Density | 8.24g/cm2 |

| Thermal Expansion Coefficient |

4.6〜5.2(303〜673K) |

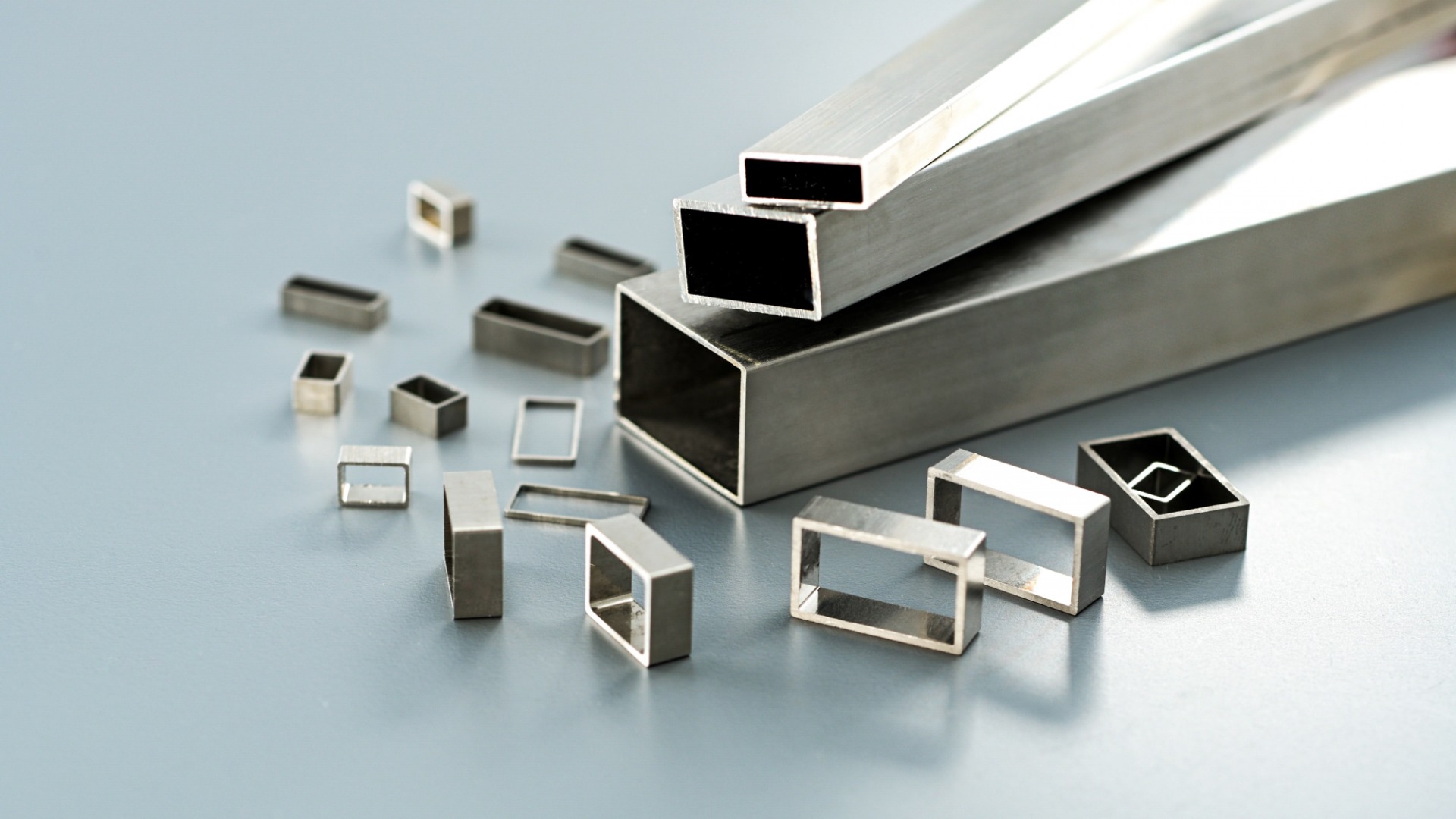

Kovar pipe production range

| Outer diameter | φ2㎜~φ40㎜ |

|---|---|

| Thickness | 0.2㎜~2.2㎜ |

| Length | Less than 6m |

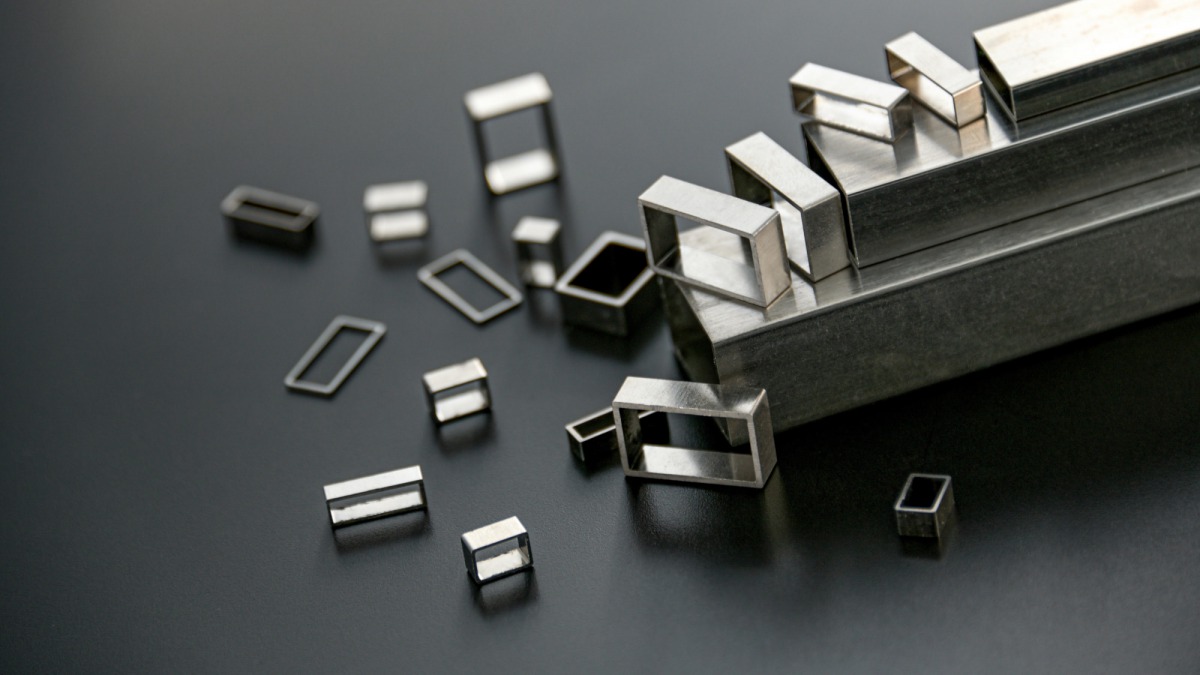

Ultra-precision cutting of Kovar pipe

Kovar is a special metal material that is hard to process due to its low thermal expansion coefficient and tenacity, but with our unique high-precision processing technology, it is possible to perform ultra-precision cutting according to the desired width, making it suitable for mass production of small electronic components. In the manufacturing process, when we deal with precious materials such as rare metals, we carry out strict quality control in each process to ensure high-quality manufacturing.

Kovar seamless pipe

High-performance materials that open up the future of precision machinery

Trust and achievements built up through optical devices

The Kovar seamless pipes we produce have demonstrated their outstanding performance to the fullest in the field of precision optical devices such as optical communications and optical sensors. We strictly adhere to consistent quality control, from the careful selection of raw materials to the final product. Thanks to the technology and experience we have cultivated over many years, we have maintained a complaint rate that is close to zero, earning us the deep trust of our customers. With a thermal expansion coefficient very close to that of glass and semiconductor materials, Kovar seamless pipes minimize stress caused by temperature changes and continue to demonstrate their true value in extremely delicate environments where high precision and airtight sealing are required.

Dramatically improving yield and reliability with a groundbreaking manufacturing method

There are two major issues facing Kovar pipes currently available on the market.

Inefficiency caused by "machining" from expensive round bars or plates

Most common Kovar pipe products are manufactured by cutting out expensive Kovar round bars or plates. This method results in a lot of valuable material becoming scrap, resulting in a low yield. As a result, material costs and processing time increase, which also affects the product price.

Quality risks associated with "welded pipes"

There are also Kovar welded pipes that are made by bending and welding plate material, but the welded parts have the potential risk of causing stress concentrations during subsequent processing or in the environment in which the product is used, which can lead to defects.The reliability of these welded parts is always in question, especially in applications that require strict airtightness.

Our Kovar seamless pipes provide a fundamental solution to these deep-rooted issues.

Innovative manufacturing reduces costs by eliminating material waste

Our unique seamless manufacturing technology enables customers to dramatically reduce material waste and cut out parts from round bars, significantly reducing the number of processing steps required. This contributes greatly to reducing total costs and improving production efficiency.

Seamless design brings ultimate reliability

The seamless construction eliminates the risk of quality issues or defects caused by welding, providing maximum peace of mind in any application requiring unparalleled tightness and unwavering reliability throughout its lifespan.

Inefficiency caused by "machining" from expensive round bars or plates

Most common Kovar pipe products are manufactured by cutting out expensive Kovar round bars or plates. This method results in a lot of valuable material becoming scrap, resulting in a low yield. As a result, material costs and processing time increase, which also affects the product price.

Quality risks associated with "welded pipes"

There are also Kovar welded pipes that are made by bending and welding plate material, but the welded parts have the potential risk of causing stress concentrations during subsequent processing or in the environment in which the product is used, which can lead to defects.The reliability of these welded parts is always in question, especially in applications that require strict airtightness.

Our Kovar seamless pipes provide a fundamental solution to these deep-rooted issues.

Innovative manufacturing reduces costs by eliminating material waste

Our unique seamless manufacturing technology enables customers to dramatically reduce material waste and cut out parts from round bars, significantly reducing the number of processing steps required. This contributes greatly to reducing total costs and improving production efficiency.

Seamless design brings ultimate reliability

The seamless construction eliminates the risk of quality issues or defects caused by welding, providing maximum peace of mind in any application requiring unparalleled tightness and unwavering reliability throughout its lifespan.

Innovative manufacturing reduces costs by eliminating material waste

Our unique seamless manufacturing technology enables customers to dramatically reduce material waste and cut out parts from round bars, significantly reducing the number of processing steps required. This contributes greatly to reducing total costs and improving production efficiency.

Seamless design brings ultimate reliability

The seamless construction eliminates the risk of quality issues or defects caused by welding, providing maximum peace of mind in any application requiring unparalleled tightness and unwavering reliability throughout its lifespan.

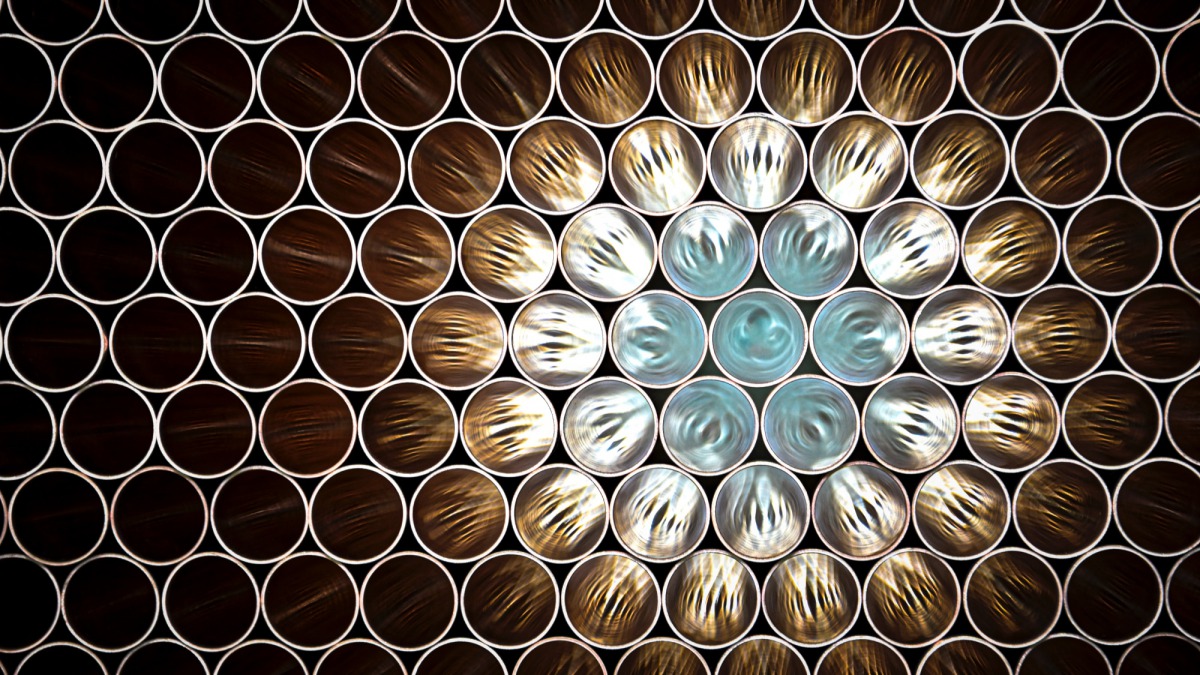

Seamless Kovar tubing ideal for vacuum components

We manufacture Kovar seamless pipes, ideal for vacuum components such as vacuum tubes and electron tubes, for domestic and international manufacturers.

Our proprietary drawing process achieves Kobar seamless pipes with uniform wall thickness and superior dimensional accuracy. They serve diverse applications requiring airtightness and thermal expansion control, such as vacuum-sealed components, electronic device packages, and medical/analytical equipment.

Why choose Kovar pipe?

High-precision materials with outstanding properties that are essential for electronic components

Kovar manufactures high-quality pipes by utilizing a special alloy of iron, nickel, and cobalt, its affinity with glass and ceramics, and the following features:

Feature1Low thermal expansion

Because it has a thermal expansion coefficient very close to that of glass, ceramics, and semiconductor materials, it suppresses the generation of thermal stress at the joints between these different materials, significantly reducing the risk of breakage and leaks.

Feature2High airtightness

The seamless structure makes it difficult for impurities and minute defects to form inside, providing excellent airtightness. It is ideal for applications that require strict airtightness, such as vacuum equipment and high-pressure environments.

Feature3Excellent processability

We are capable of high-precision machining, and can flexibly accommodate complex shapes and minute dimensional accuracy to meet your detailed requests. Astonishing dimensional accuracy: Although it varies depending on the size, we can handle extremely precise tolerances of ±0.03 mm. This is a truly "usable" figure for designers who require high precision that is difficult to achieve with other companies' products.

Feature4Supports a wide range of sizes and shapes

We can handle a wide range of sizes, from the extremely thin φ1.0mm to φ40mm outer diameter, and the extremely thin 0.2mm to 2.2mm wall thickness. Furthermore, we are not limited to standard round pipes, but also excel at manufacturing special irregular shaped pipes such as square shapes. We will help you turn your original design ideas into reality with our reliable technical capabilities.

Feature5Supports small-lot production

We can handle orders from as little as 10 kg, so we can flexibly meet the needs of prototypes at the research and development stage and small-lot production of a wide variety of products.We are not only able to handle large lots, but also accommodate the requests of engineers who want to "try it out first."

Feature6Stable quality

Thanks to our many years of experience and unique manufacturing process, each and every product meets consistent and stable quality standards.

Feature1Low thermal expansion

Because it has a thermal expansion coefficient very close to that of glass, ceramics, and semiconductor materials, it suppresses the generation of thermal stress at the joints between these different materials, significantly reducing the risk of breakage and leaks.

Feature2High airtightness

The seamless structure makes it difficult for impurities and minute defects to form inside, providing excellent airtightness. It is ideal for applications that require strict airtightness, such as vacuum equipment and high-pressure environments.

Feature3Excellent processability

We are capable of high-precision machining, and can flexibly accommodate complex shapes and minute dimensional accuracy to meet your detailed requests. Astonishing dimensional accuracy: Although it varies depending on the size, we can handle extremely precise tolerances of ±0.03 mm. This is a truly "usable" figure for designers who require high precision that is difficult to achieve with other companies' products.

Feature4Supports a wide range of sizes and shapes

We can handle a wide range of sizes, from the extremely thin φ1.0mm to φ40mm outer diameter, and the extremely thin 0.2mm to 2.2mm wall thickness. Furthermore, we are not limited to standard round pipes, but also excel at manufacturing special irregular shaped pipes such as square shapes. We will help you turn your original design ideas into reality with our reliable technical capabilities.

Feature5Supports small-lot production

We can handle orders from as little as 10 kg, so we can flexibly meet the needs of prototypes at the research and development stage and small-lot production of a wide variety of products.We are not only able to handle large lots, but also accommodate the requests of engineers who want to "try it out first."

Feature6Stable quality

Thanks to our many years of experience and unique manufacturing process, each and every product meets consistent and stable quality standards.

The possibilities of Kovar pipes expand into new areas

Medical Devices

Vacuum tubes for X-ray tubes, CT scans, etc.

By utilizing high airtightness and low thermal expansion, the internal vacuum state can be stably maintained, contributing to the longer life of medical equipment and improved diagnostic reliability.

Medical sensors and probes

They play an important role in supporting precise signal transmission in environments where biocompatibility and corrosion resistance are required.

Aerospace and Defense

Hermetically sealed parts for space equipment

They are essential for highly reliable airtight containers and connecting parts that reliably protect internal equipment from the harsh temperature fluctuations and vacuum environment of outer space.

Aircraft sensors and instruments

These parts, which require high reliability and durability in extreme environments, support safe operation.

Analytical and measuring equipment field

Vacuum chamber parts for mass spectrometers, gas chromatographs, etc.

It provides a stable measurement environment for analytical equipment that requires an extremely high degree of vacuum, contributing to improved data accuracy.

Various sensors and detectors

It is ideal for protective tubes and housings for sensors that require precise signal transmission and temperature stability.

High frequency/microwave devices

Vacuum microwave tubes, traveling wave tubes (TWTs)

During high-frequency signal transmission, distortion caused by thermal expansion is minimized, supporting stable, highly efficient operation.

High frequency connector parts

It provides stable electrical characteristics for components that require precise impedance matching.

Medical Devices

Vacuum tubes for X-ray tubes, CT scans, etc.

By utilizing high airtightness and low thermal expansion, the internal vacuum state can be stably maintained, contributing to the longer life of medical equipment and improved diagnostic reliability.

Medical sensors and probes

They play an important role in supporting precise signal transmission in environments where biocompatibility and corrosion resistance are required.

Aerospace and Defense

Hermetically sealed parts for space equipment

They are essential for highly reliable airtight containers and connecting parts that reliably protect internal equipment from the harsh temperature fluctuations and vacuum environment of outer space.

Aircraft sensors and instruments

These parts, which require high reliability and durability in extreme environments, support safe operation.

Analytical and measuring equipment field

Vacuum chamber parts for mass spectrometers, gas chromatographs, etc.

It provides a stable measurement environment for analytical equipment that requires an extremely high degree of vacuum, contributing to improved data accuracy.

Various sensors and detectors

It is ideal for protective tubes and housings for sensors that require precise signal transmission and temperature stability.

High frequency/microwave devices

Vacuum microwave tubes, traveling wave tubes (TWTs)

During high-frequency signal transmission, distortion caused by thermal expansion is minimized, supporting stable, highly efficient operation.

High frequency connector parts

It provides stable electrical characteristics for components that require precise impedance matching.

Support for development of clad materials using Kovar

Joint development that opens up unknown possibilities

We do not only provide Kovar seamless pipes, but also aim to be a partner that supports our customers' innovative challenges with our technology. Clad materials that combine Kovar with dissimilar metals have the potential to combine the properties of each material and bring out new functions and performance that cannot be achieved with a single material. Utilizing the Kovar manufacturing technology and knowledge we have cultivated over many years, we will strongly support your research and development of clad materials using Kovar. From basic studies to prototyping and evaluation, we will help you create the products of the future through joint development tailored to your needs.

Adding new value to your manufacturing

Our Kovar seamless pipes offer numerous benefits to your products, including improved reliability, longer life, smaller size, and higher precision. In particular, the reduction in material costs and the significant reduction in defect rates will be major advantages that directly contribute to your company's productivity and profitability. Please consider our Kovar pipes as a material replacement for existing designs or as a key material for developing innovative new products.

Materials Processing

- Cold drawn

- Swaging process

- Metal straightening

- Correction

- Cutting process

- Heat treatment

- Solvent degreasing process

- Polishing

Functional

- Magnetic

- Thinning

- Sealing

- Surface roughness

- High dimensional accuracy

- Quality stable

- Inflatable

- Sealability

Industrial fields

- Optical fiber communication